Lifting Magnet

for Shovel

Safe and Efficient Steel Material Handling

Sinfonia's Lifting Magnet plays an important role in the transportation of various steel materials, including scrap, steel mills, steel centers, and steel processors. As a leading manufacturer of lifting magnets, we have earned a high reputation and reliability in Japan and around the world. We will continue to further refine our "Lifting Magnet" technology to meet the new needs of users.

Lifting Magnet for Scrap Handling

Features

- Aluminum wire coil reduces the weight of the magnetic circuit

Simple structure, large suspension capacity, and strong magnetic flux are the strongest in the industry. The lifting capacity per unit price is also the strongest in the industry. - High lifting efficiency and low power consumption

Power consumption has been reduced while lifting capacity is increased. It is possible to replace other companies' magnets without changing the power supply unit. - Emergency Preparedness

A device can be attached to safely hold a suspended load in the event of an unexpected power failure of the power supply or trouble with the equipment. (Guaranteed for 5 minutes) - Capable of handling high-frequency field work

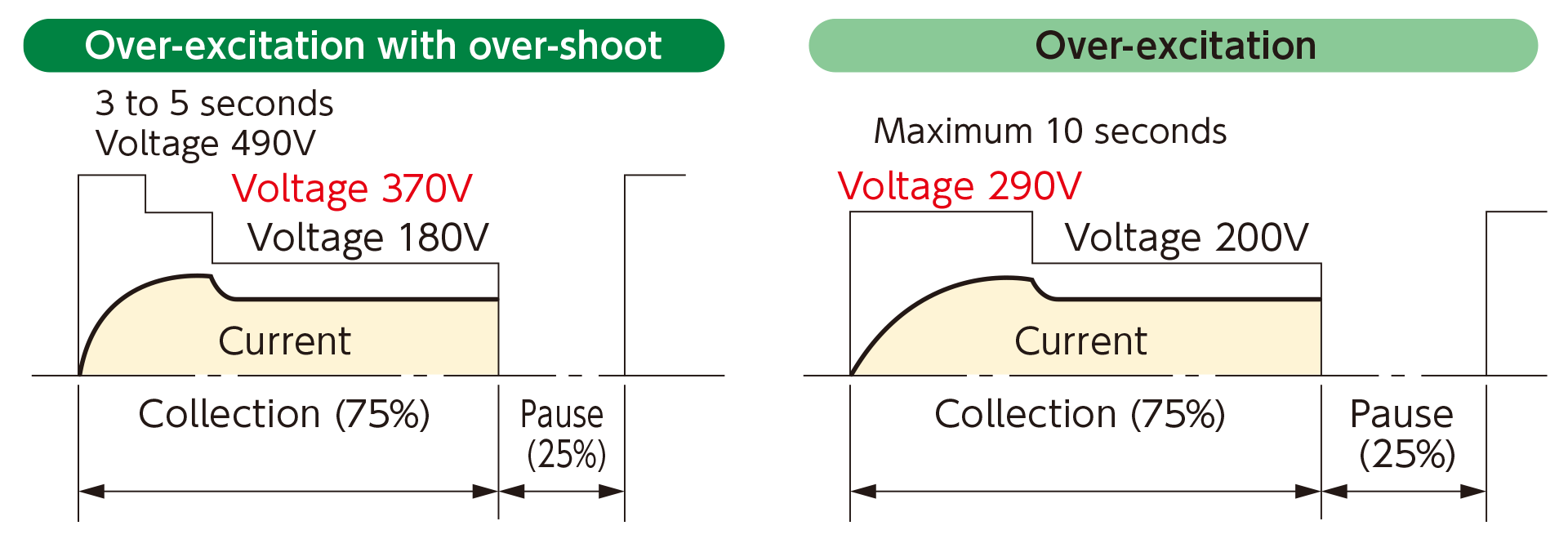

While the standard usage rate is 50%, the system can withstand up to 75%. The appropreate model can be provided to sites where high frequency operation is required. - Overshoot/Over-exit

Large lifting magnets are equipped with overshoot and over-excite controls that rapidly ramp up the electric current, further increasing capacity and shortening the handling cycle.

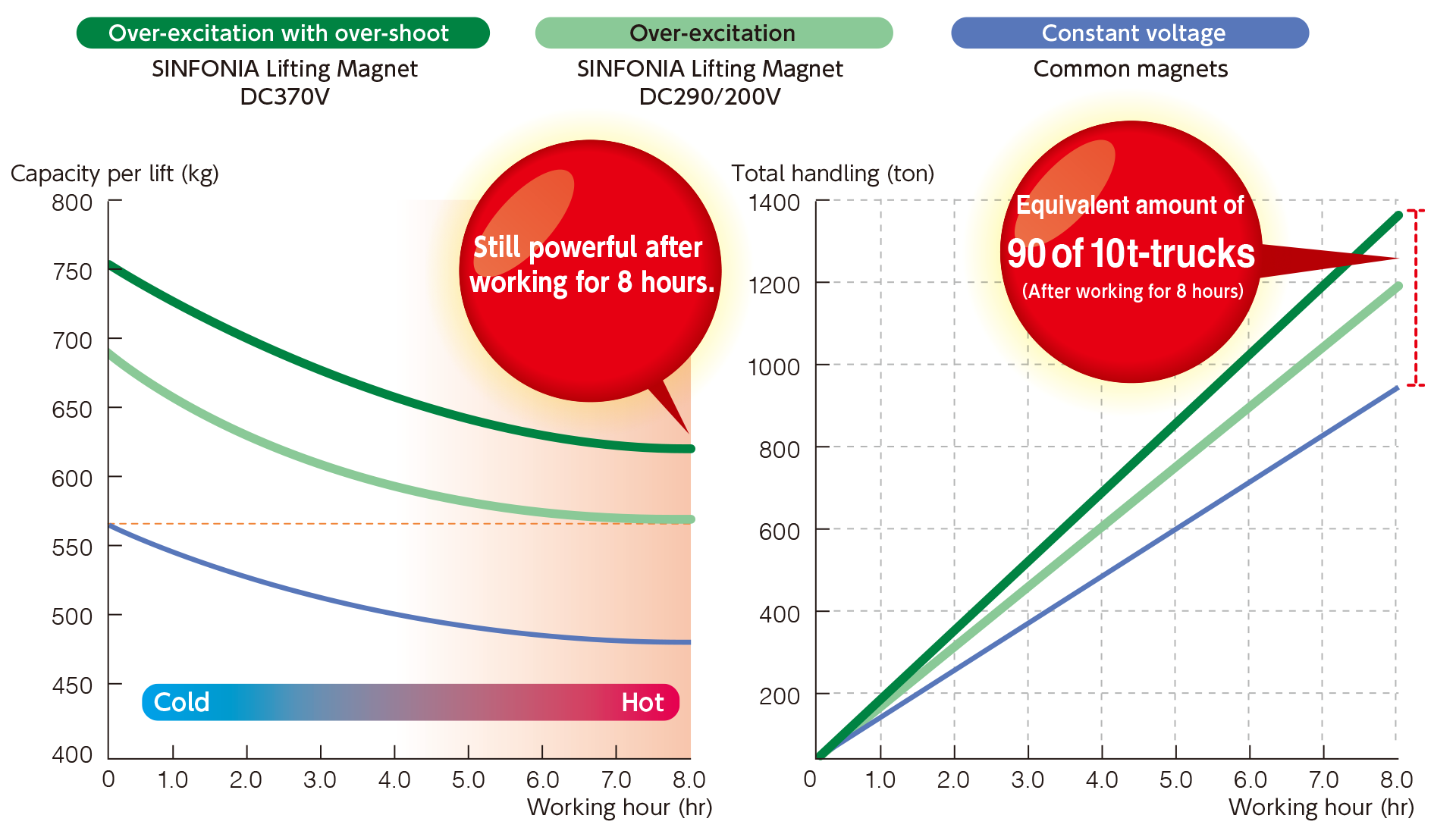

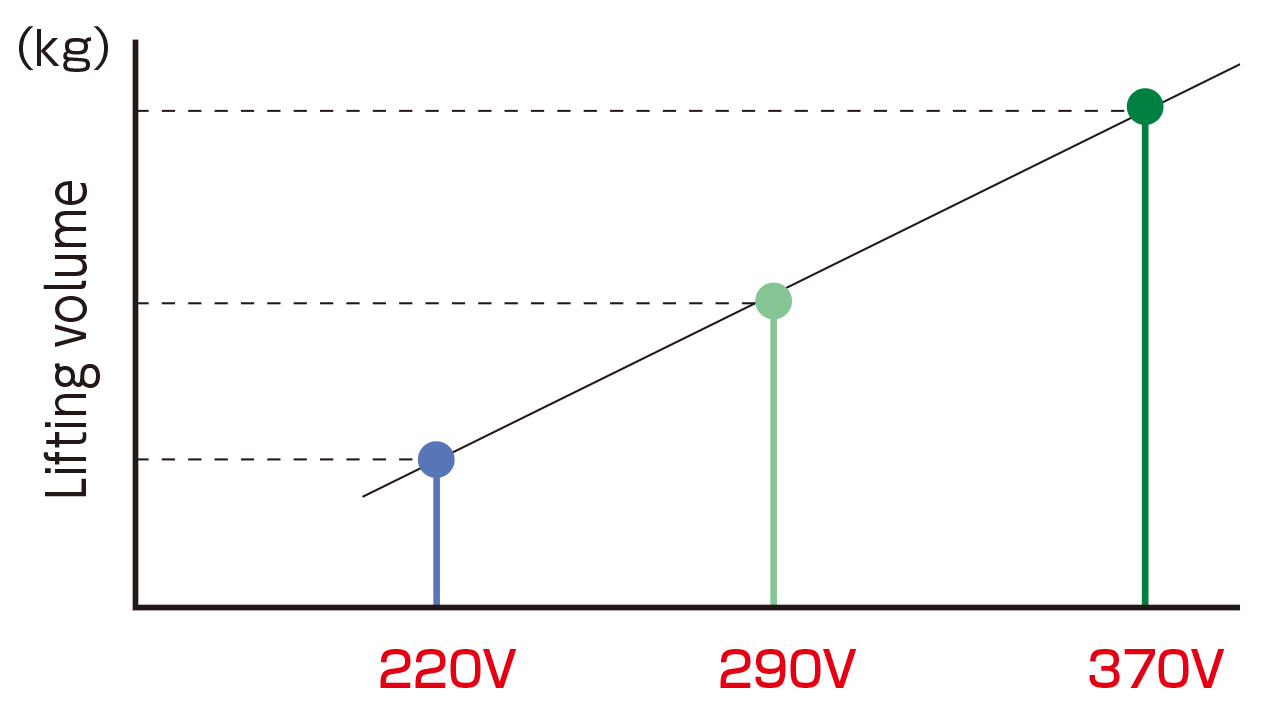

Comparison of lifting capacity

Powerful lifting capacity improves work efficiency!

Comparison of lifting capacity by work hour between competitor’s and our lifting magnet

Application

for Shovel

Steel Plate Handling

Steel Pipe Handling

Coil Handling

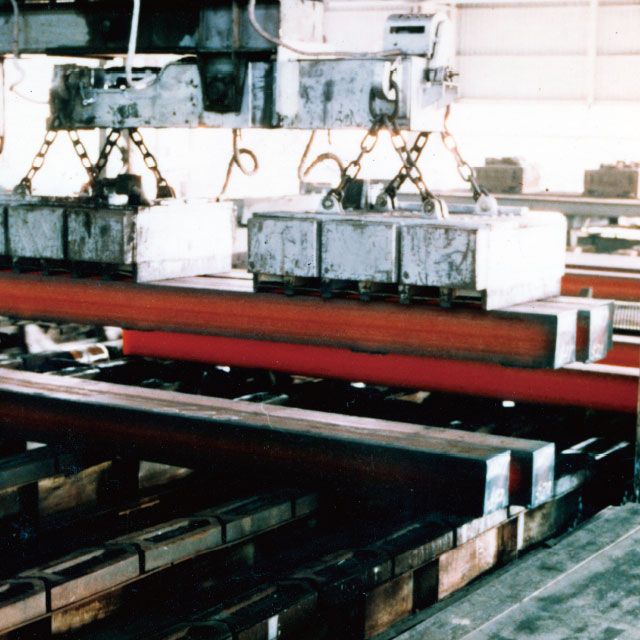

Slab Handling

H-shaped Steel Handling

Bundled Steel Bars Handling

Billets and Blooms Handling

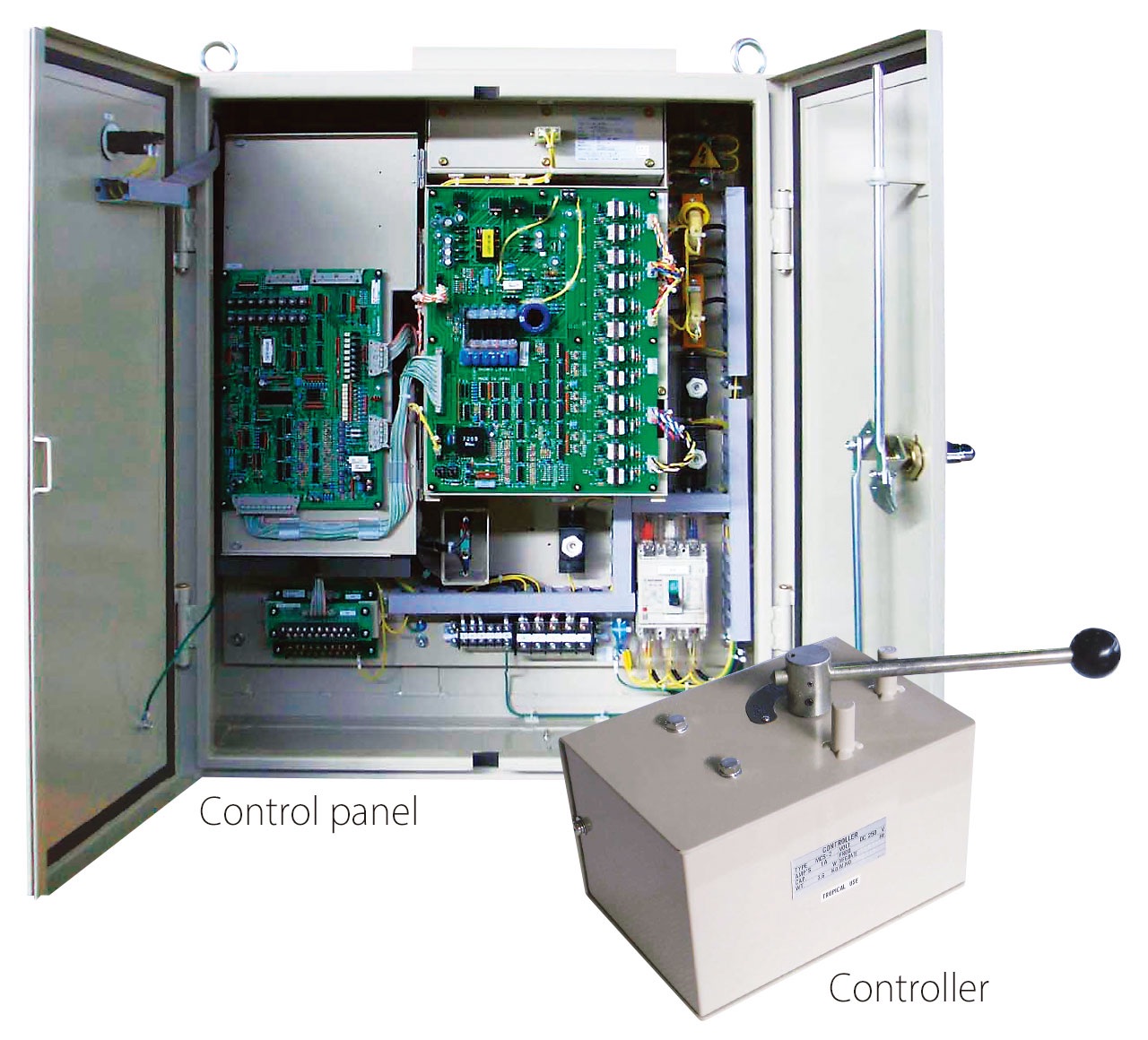

Control Panel

The use of Sinfonia's control panel contributes to the improvement of your company's work efficiency with quick suction and release.

- Improved lifting capacity and work efficiency

The lifting capacity is increased and the current rise time is shortened to improve work efficiency because the thyristor on the positive excitation side is fully excited for a certain period of time to over-excite the Lifmag® during scrap pickup. - Extremely smooth release

When reverse-excited, Lifmag® is controlled by a constant-current control system, which enables smooth release of all types of scrap. - No matter where it is used

The power supply panel is totally enclosed and dustproof, and the electronic circuits are fully protected for safe use. - Compatible with all control methods

Input and output patterns can be selected by a switch on the printed circuit board, making this all-mighty type compatible with all control methods.

Excite effect

Voltage-current relationships by control method