Contract Testing Services

Motor Performance/Efficiency Evaluation

We offer a wide range of testing services for motors and inverters, from performance and efficiency testing to certification and standards compliance testing.

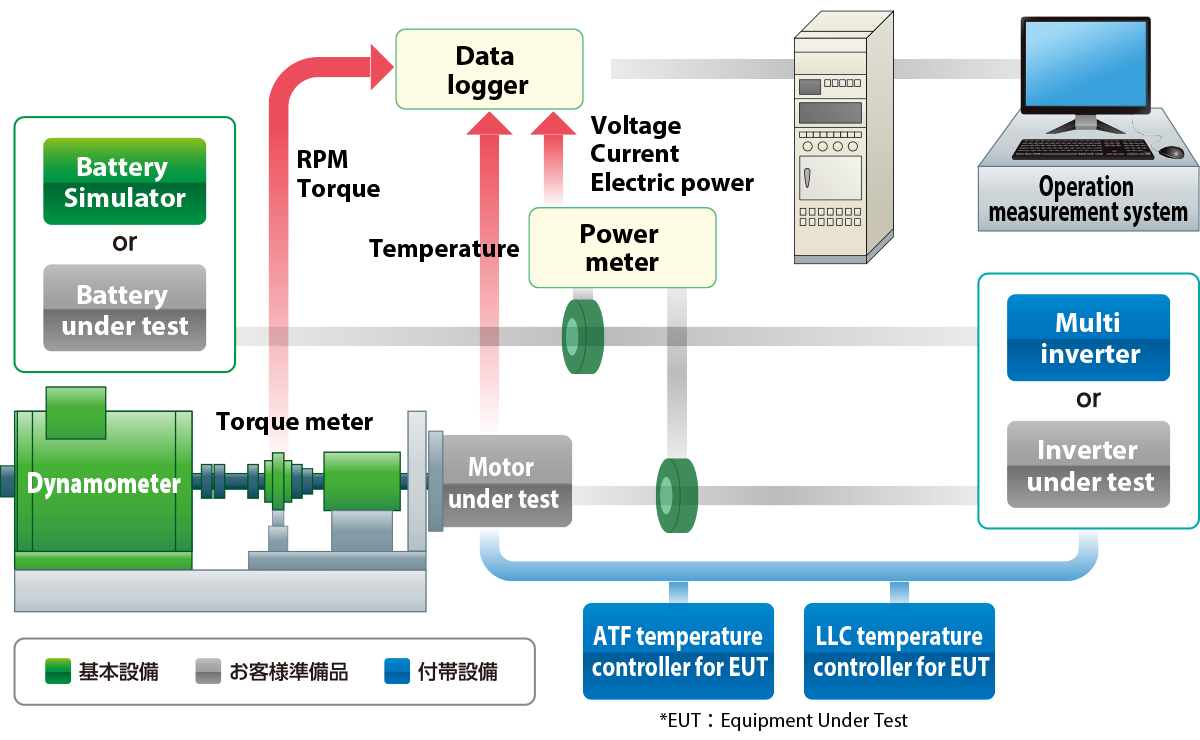

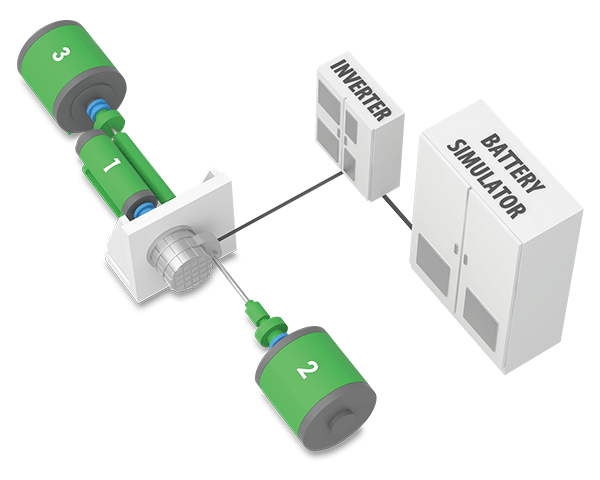

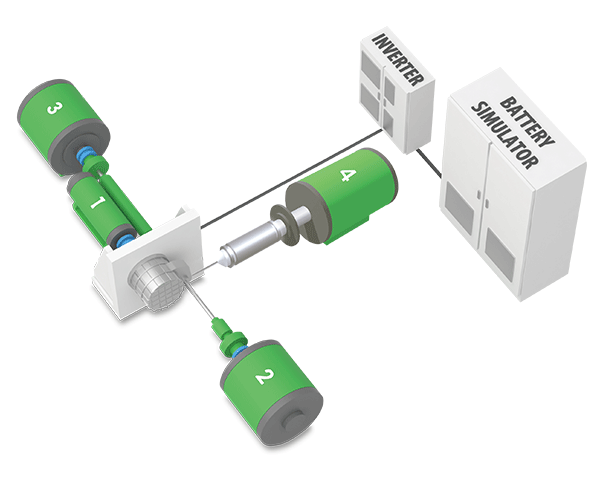

System Configuration Diagram

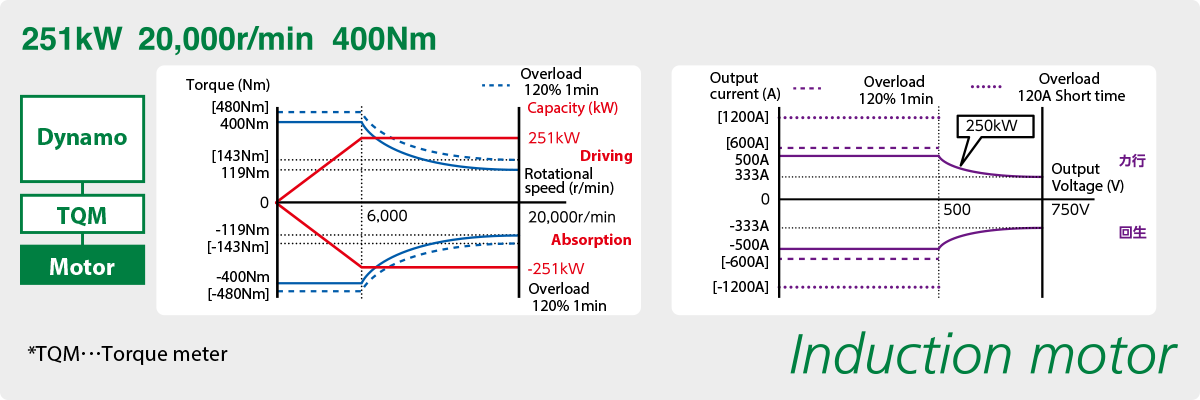

S1 Bench (High-precision measurement specification) ~High-speed dynamo+battery simulator~

Intermediate bearing-less, 20,000 rpm test.

The operating range may be limited depending on the weight of the EUT* motor and the directly connected structure.

*EUT: Equipment Under Test

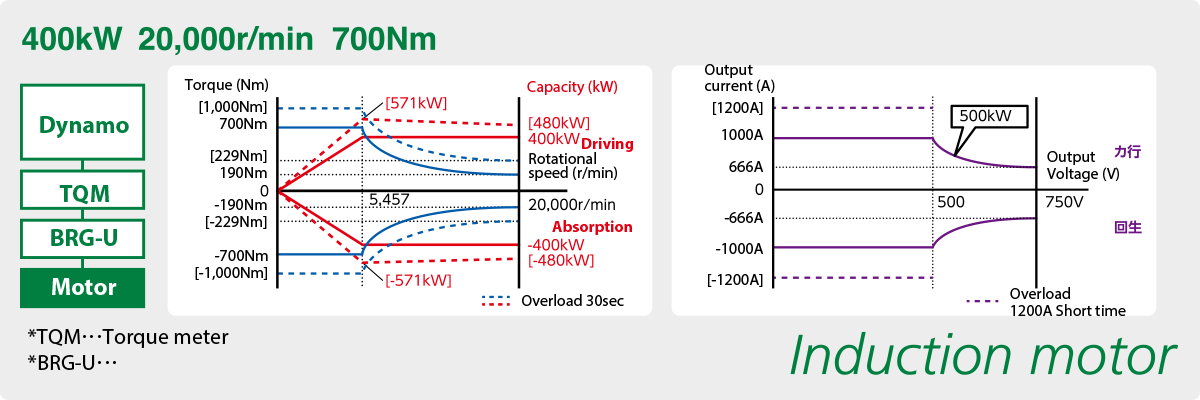

S2 Bench (Large-capacity specification) ~High-speed dynamo+battery simulator~

The only one in Japan to achieve 20,000 rpm 400kW 700Nm specifications.

The operating range may be limited depending on the weight of the EUT* motor and the directly connected structure.

*EUT: Equipment Under Test

Multi inverter

3-phase PWM system (sine, over-modulated, square wave)

Carrier frequency: up to 10 kHz

Basic wave voltage control available

Protective devices: input overvoltage, output overcurrent, input overvoltage, output overcurrent, current limit, control power supply voltage drop, etc.

Enable to energize by IdIq, VdVq instructions from host controller

Axial torque feedback control along MTPA line and maximum efficiency line possible

Measurement

Steady-state value measurement in combination with control system

Basic measurement items: fundamental wave (voltage, current, power), harmonics, rotation speed, torque, various temperatures (thermocouples, thermistors, resistance thermometer)

Induced voltage/temperature characteristics evaluation

Current advance/torque characteristics

NT characteristics

dq-axis inductance measurement

MTPA line acquisition, maximum efficiency line acquisition

Efficiency map

ATF temperature controller

Flow rate range: 3 to 20[L/min]

Temperature range: primary cooling water temperature to 150°C

Oil type can be specified

LLC temperature controller

Flow rate range: 3 to 20[L/min]

Temperature range: primary cooling water temperature to 90°C

Refrigerant can be specified.

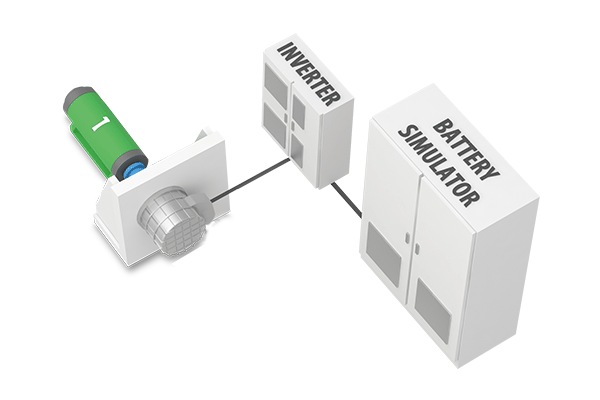

Drive Component Evaluation

Testing of up to 4-axis configurations and combination with multi inverters for evaluation of HV units, etc.

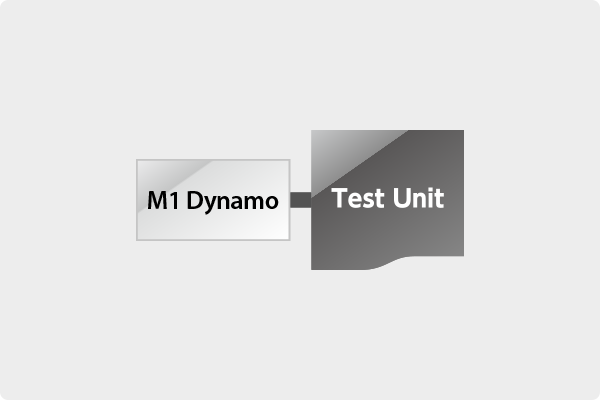

Single Axis Test Configuration

- 314kW 5,000/8,000r/min 600Nm

Motor Evaluation

Layout is an image only.

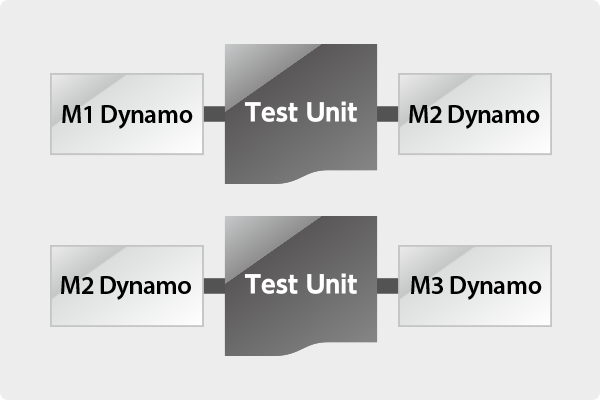

Two-axis test configuration

- 314kW 5,000/8,000r/min 600Nm

- 600kW 1,910/8,000r/min 3,000Nm

FR-T/M Endurance Test

Layout is an image only.

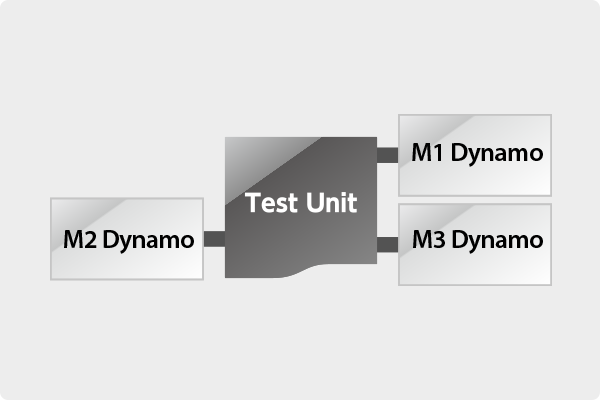

Triaxial test configuration

- 314kW 5,000/8,000r/min 600Nm

- 500kW 1,200/2,400r/min 3,980Nm

- 500kW 1,200/2,400r/min 3,980Nm

FF-T/M endurance test

Oil performance and endurance evaluation

Test contents and dynamometer specifications other than those listed are also available.

Layout is an image only.

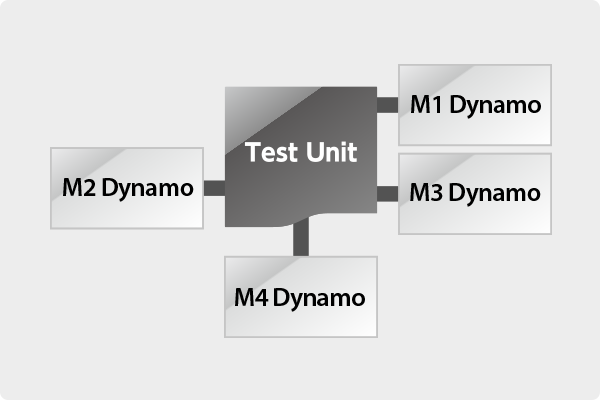

4-axis test configuration

- 314kW 5,000/8,000r/min 600Nm

- 500kW 1,200/2,400r/min 3,980Nm

- 500kW 1,200/2,400r/min 3,980Nm

- 600kW 1,910/8,000r/min 3,000Nm

FF-T/M endurance test

Oil performance and endurance evaluation

Multi inverter

4WD-T/M durability test

Test contents and dynamometer specifications other than those listed are also available.

Layout is an image only.

Combined battery simulator testing is also available. Please contact us for details.

Configuration Example

Free layout for various testing!