What is a vibrating equipment?

Most factory production facilities are lined with conveying equipment used to transport materials. A vibrating equipment is a type of conveying equipment that conveys materials by applying special vibrations to a semi-tubular conveying section called a trough. In addition to conveying materials, vibrating equipment can add value in a variety of ways, such as sifting materials according to size, conveying materials while performing uniform drying and cooling, and conveying powders and food products without contamination by foreign objects by attaching covers to the troughs.

For this reason, vibrating equipment is used in various manufacturing sites, for example, in the food and chemical industries, which require high-precision humidity control and a highly sanitary environment; in steel mills and recycling sites, where durability is required; and in the foundry industry, where heated materials are conveyed. Belt conveyors are widely used for conveying materials, but vibrating equipment can convey materials that cannot be conveyed by belt conveyors.

Vibrating conveyor systems have a long history and were already in use in Europe and the United States more than 100 years ago. Sinfonia developed its own vibrating equipment, the "Tobatron," in 1951. Two years later, we introduced the most advanced vibrating conveyor technology of the time from Cintron Corporation in the U.S. Over the last half century, we have steadily built up our technological capabilities and achievements. Today, as one of the world's leading comprehensive manufacturers of vibrating equipment, we use the technology and experience we have cultivated over the years to meet all kinds of needs related to powders, granulates, and other materials.

Principle of Conveyance by vibrating equipment

-

Vibration causes trough to shift to lower left.

-

Speed of shift causes material in trough to fall forward.

-

Trough shifts to upper right to return to original position.

-

Material is also thrown up and forward.

-

This process is repeated.

The material to be conveyed leaps forward at right angles to the springs of the vibrating equipment.

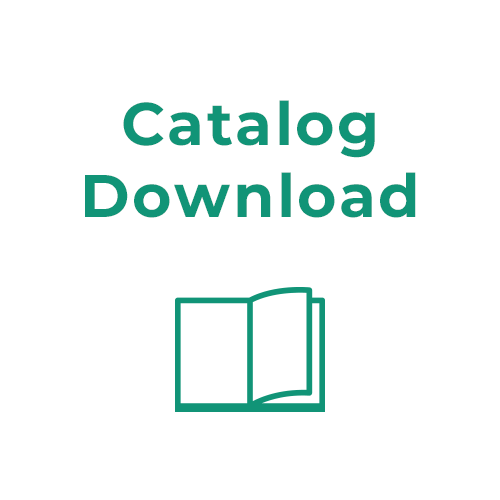

Vibrating Conveyors

A wide range of models, from the conventionals to the uniques

High-performance vibrating conveyors transfer powdered or granular materials by means of an appropriate type and level of vibration, while processing such as drying, cooling, sorting, cleaning or draining takes place. Comprising many types of

trough and powerful vibrating generators, our comprehensive product line-up offers conventional models as well as exciting new types utilizing horizontal vibration.

Their notable features include vibro-isolating construction that stops transmission of the vibration to the floor, low noise, and easily adjustable vibratory characteristics.

They offer new means of conveyance for the efficient processing of all sorts of particulate materials: foodstuffs, chemicals, pharmaceuticals, fertilizers, glass, cement, mineral ores and coal, and contribute to the streamlining and productivity of material processing lines.

Applications

| Foodstuffs |

● |

|---|---|

| Sugar refining |

● |

| Feedstuffs |

● |

| Fertilizers |

● |

| Chemicals |

● |

| Glass |

● |

| Ceramics |

● |

|---|---|

| Plastics |

● |

| Synthetic fibers |

● |

| Paper making |

● |

| Tobacco products |

● |

| Iron and steel |

● |

| Crushed stone |

● |

|---|---|

| Mining |

● |

| Sanitary ware |

● |

| Casting and forging |

● |

| Asphalt |

● |

| Metals |

● |

| Waste processing |

● |

|---|---|

| Vehicles |

● |

| Machinery |

● |

| Electrical equipment |

|

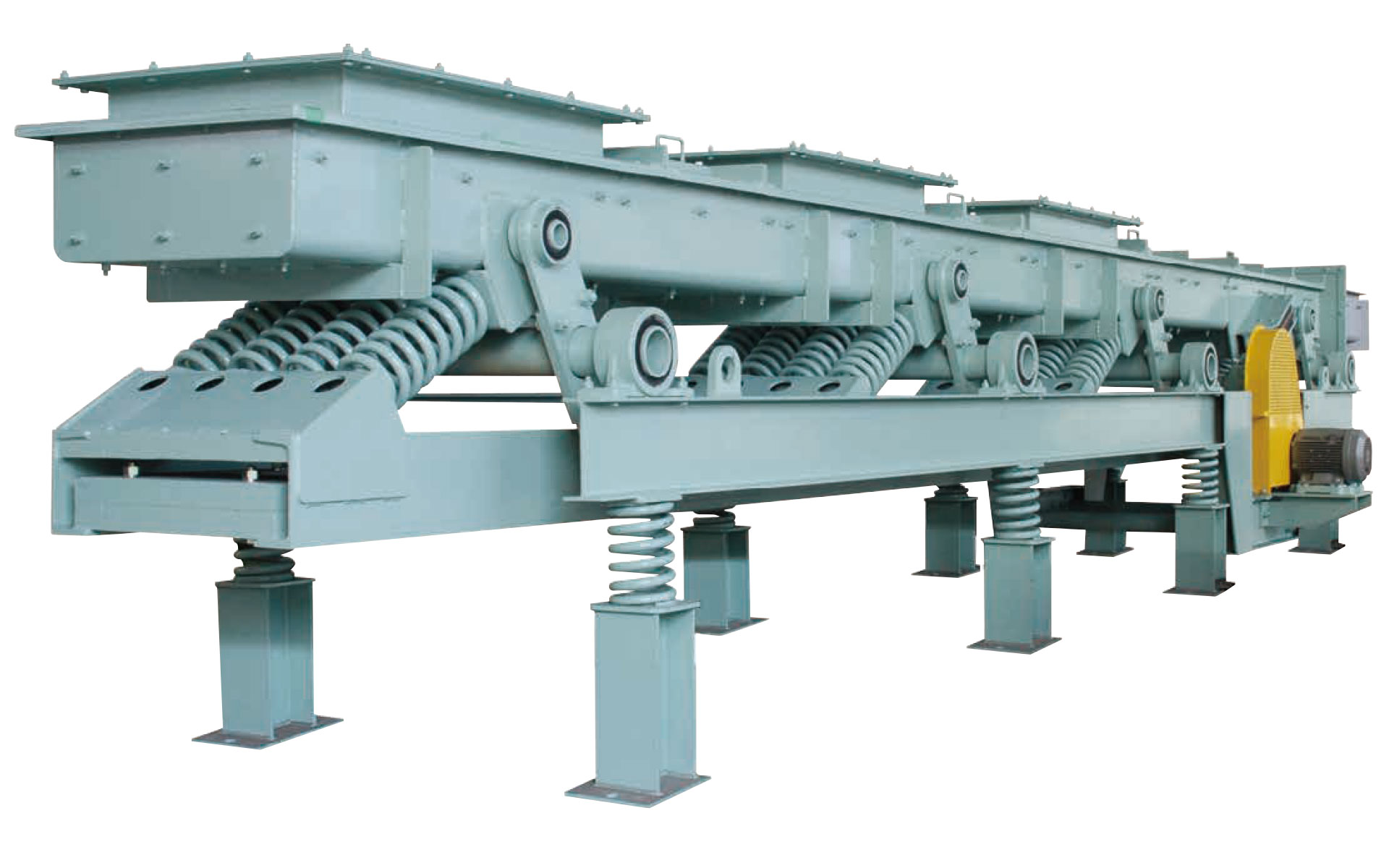

Vibrating Screens

Sifting and sorting suitable for any materials and uses

Vibrating screens are used for many different purposes: sorting by shape, sorting into grain sizes, eliminating foreign matter, preparing material for later processing, and so on. The types of screens in use are becoming more diverse, reflecting the different shapes, properties and flow characteristics of the materials they are used with, as well as the different environments and ways in which they are used.

We produces vibrating screens in 10 series, using various types of vibration: electromagnetic, eccentric-crank, direct vibration from a vibrating motor, horizontal swivel vibration, etc. Responding to

calls for enhanced and more efficient processing of particulate materials, we can supply the optimal screening equipment to suit any purpose and any materials, from fine powder to lumpy matter, by bringing together the appropriate mesh size, processing capacity and type of vibration.

Applications

| Foodstuffs |

● |

|---|---|

| Sugar refining |

● |

| Feedstuffs |

● |

| Fertilizers |

● |

| Chemicals |

● |

| Glass |

● |

| Ceramics |

● |

|---|---|

| Plastics |

● |

| Synthetic fibers |

● |

| Paper making |

|

| Tobacco products |

● |

| Iron and steel |

● |

| Crushed stone |

● |

|---|---|

| Mining |

● |

| Sanitary ware |

● |

| Casting and forging |

● |

| Asphalt |

● |

| Metals |

|

| Waste processing |

● |

|---|---|

| Vehicles |

|

| Machinery |

|

| Electrical equipment |

|

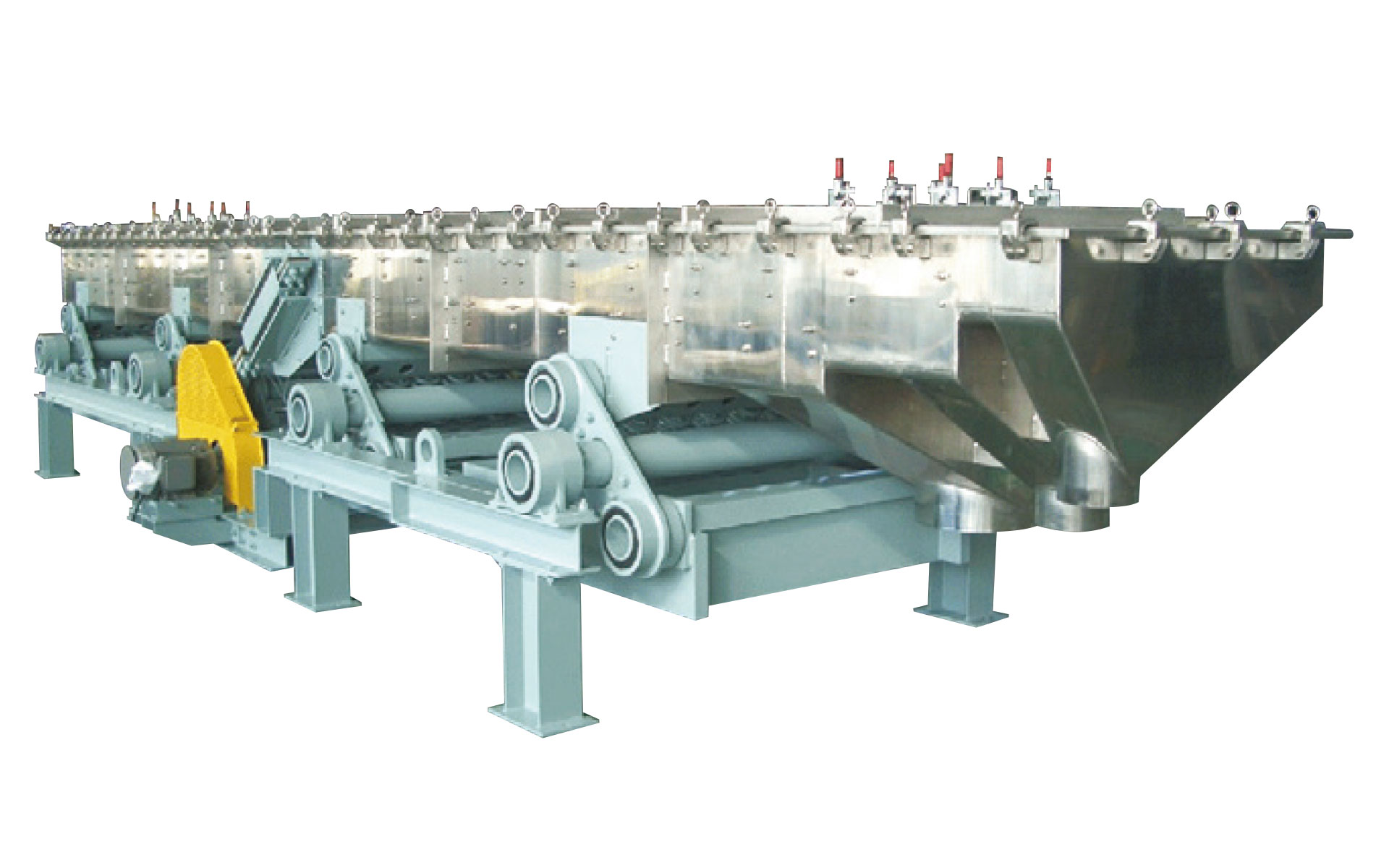

Vibrating Feeders

Swift and precise feeding of all sorts of particulates

Vibrating feeders serve a wide range of applications, from the fixed-quantity supply of granular materials to the control of flow for processing. We supply three basic types of feeders: electromagnetic feeders, rubber-spring feeders that generate vibration with a rotating unbalanced weight, and RV feeders

that use vibrating motors. All of them feature outstanding performance in fixed quantity supply, due to high feed precision, as well as excellent cut-off characteristics and convenient control of supply quantity.

Whether it’s a single unit, an assembly of units or a combination with weighing or other control devices, we can supply the ideal vibrating feeder to suit the grain size and characteristics of the material to be handled, and the supply quantity required, bringing greater precision, automation and streamlining to processing.

Applications

| Foodstuffs |

● |

|---|---|

| Sugar refining |

● |

| Feedstuffs |

● |

| Fertilizers |

● |

| Chemicals |

● |

| Glass |

● |

| Ceramics |

● |

|---|---|

| Plastics |

● |

| Synthetic fibers |

● |

| Paper making |

● |

| Tobacco products |

● |

| Iron and steel |

● |

| Crushed stone |

● |

|---|---|

| Mining |

● |

| Sanitary ware |

● |

| Casting and forging |

● |

| Asphalt |

● |

| Metals |

● |

| Waste processing |

● |

|---|---|

| Vehicles |

● |

| Machinery |

● |

| Electrical equipment |

● |

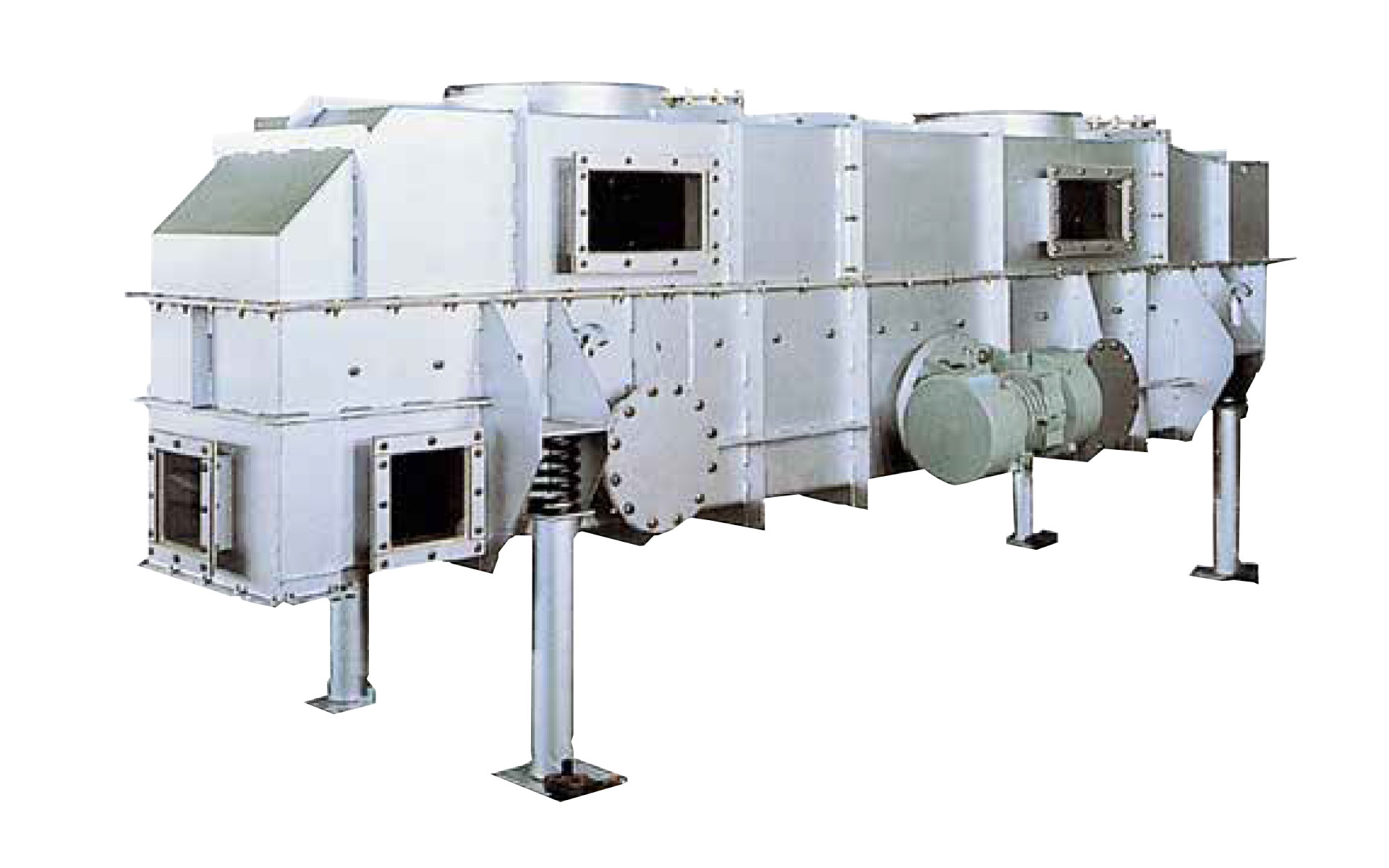

Vibrating Dryer-Cooler System

For drying and cooling during conveyance

Vibrating dryer-cooler system comprises a vibrating conveyor, cooling source, fan, and dust removal and extraction equipment. Vibration is used to generate material flow, and air driven through the base of the trough dries and cools the material evenly. By adjusting vibratory characteristics the conveyance/processing time can be freely selected for detailed and precise control of the material’s final temperature and moisture content. Thus, the ideal drying and cooling processing can be obtained for different types of material, as well as different processing conditions and objectives.

Our equipment enjoys an excellent reputation in providing for high quality and high efficiency processing of this type in many fields: not only foodstuffs but chemicals, feeds, synthetic resins, ceramics, and more.

Applications

| Foodstuffs |

● |

|---|---|

| Sugar refining |

● |

| Feedstuffs |

● |

| Fertilizers |

● |

| Chemicals |

● |

| Glass |

● |

| Ceramics |

● |

|---|---|

| Plastics |

● |

| Synthetic fibers |

● |

| Paper making |

● |

| Tobacco products |

● |

| Iron and steel |

● |

| Crushed stone |

|

|---|---|

| Mining |

|

| Sanitary ware |

● |

| Casting and forging |

● |

| Asphalt |

● |

| Metals |

|

| Waste processing |

|

|---|---|

| Vehicles |

|

| Machinery |

|

| Electrical equipment |

|