Vibrating Conveyors

Optimal for streamlining and improving the efficiency of powder and granule treatment processes, such as conveying, screening, drying, and washing.

Powder and granular material treatment processes are required to become more sophisticated due to the emergence of new materials, diversification of needs, and improvement of productivity.

In particular, more efficient transport of powders and granulates between processes is required.

Sinfonia Technology's vibrating conveyors are high-performance conveyors that use unique vibrations suitable for powder/pellets conveying to fluidize the material while it is being conveyed.

The conveying volume and time can be freely adjusted, and drying, cooling, sorting, washing, dehydration, and other operations can be performed simultaneously and continuously during conveying.

The combination of a steel trough and a powerful vibration generator, which can handle any material, enables efficient conveying and processing of a wide range of materials, including food, chemicals, pharmaceuticals, fertilizers, glass, cement, tobacco, and other raw materials, as well as ores and coal, whether in powder, grain, or bulk form.

When combined with our various types of vibrating equipment, the system can fully demonstrate its capabilities as a versatile and organic powder/granular material processing process.

Sinfonia Technology's vibrating conveyors make it easy to streamline and upgrade the powder/granular processing process.

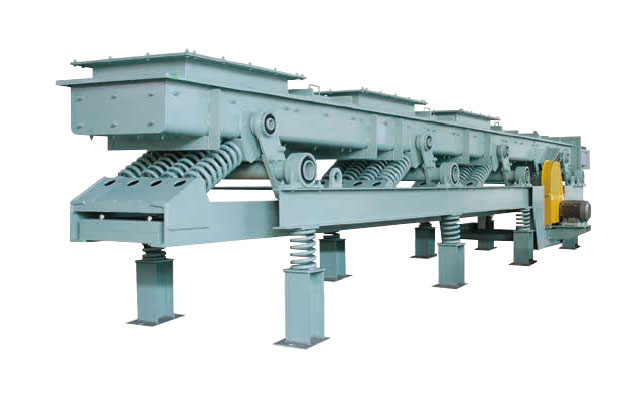

BM Type Balanced Conveyor

High efficiency/Fully balanced

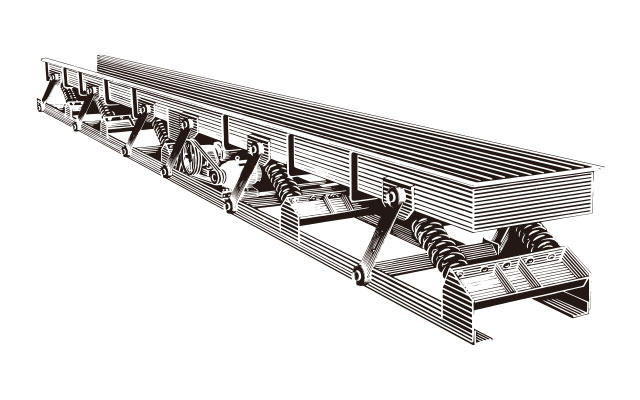

MVCB Type Balanced Conveyor

Simple construction/Anti-vibration

MV Conveyors MVC

Tough construction/Low cost

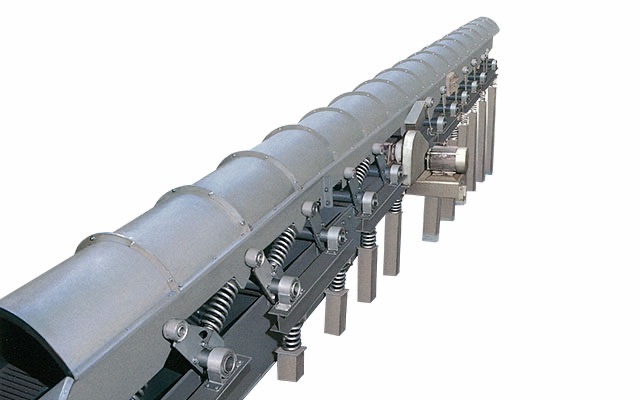

RV Conveyors RVF

Tough construction/Low cost

Tubular Trough

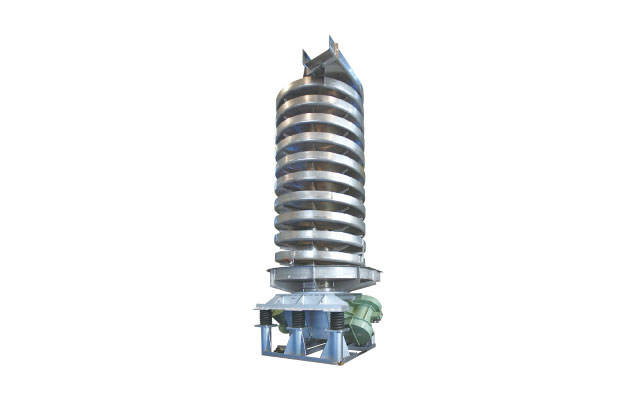

Spiral Elevator RVES

Space saving/Vertical lift

Rubber-Spring Conveyors HRC

Variable vibration angle/low bed

Slope Conveyor

Going up by vibration. The latest vibrating conveyor replaces belt conveyor.

Controller

Features

- Wide Variety

A wide variety of models are available, from the fully balanced BM type to the RV type driven by a vibration motor and the revolutionary sliding conveyor. You can select the optimum model according to your application and materials to be conveyed. - Simple structure

The trough itself does not move, but rather a simple mechanism that transmits appropriate vibration to the material being conveyed through a reciprocating motion. Moreover, the trough can be easily installed in a small space. - Suitable for a wide range of materials

Since the trough is made of steel, it can convey high-temperature materials and perform cooling operations. It is not subject to any restrictions in terms of grain size, corrosiveness, hardness or softness of the material. Depending on the material to be transported, stainless steel sheets or linings can be used. - Simultaneous drying and cooling

Drying, cooling, screening, dehydration, and other operations can be easily performed during conveyance, enabling highly efficient conveyance processing. - Energy saving

The MVCB and BM models can be operated at the appropriate frequency for the application and process, and with about half the motor capacity which significantly reduces power consumption. That contribute to the saving of maintenance costs because of big power. - Comfortable working environment

A simple installation of a dust-proof cover creates a sealed structure, allowing even fine powder to be transported without scattering, thus further improving work and maintaining comfortable working conditions. - Smooth startup and shutdown

The mvcb and bm conveyors use a unique rubber spring in the drive unit, while the rv conveyor uses electrical braking to prevent shocks when stopping, resulting in extremely smooth operation. - Easy maintenance

There are very few parts that rotate, friction, wear out, or require lubrication, so there is no need to worry about breakdowns, and maintenance and inspections are easy to perform.

Model List

| Model | Features & applications | Drive method | |

|---|---|---|---|

| BM Conveyors | BM | Fully balanced type causing no vibration pollution; handles all materials from fine to lumpy. | 3-phase induction motor, eccentric shaft action, spring resonators. |

| Balanced Conveyors | MVCB | Standard version for all types of materials. Vibration-neutralizing structure and wide applications including fully sealed conveyance. | 3-phase induction motor, eccentric shaft action, spring resonators. |

| MV Conveyors | MVC | Simple, low cost version. Suited to long distance, narrow bed conveyance. Accommodates drying, cooling etc. | 3-phase induction motor, eccentric shaft action, spring resonators (direct impact). |

| RV Conveyors | RVF | Forced vibration type that can move sticky materials smoothly. Rate of flow easily adjustable. | Forced vibration generated by rotary vibrator (vibration motor). |

| RVF-φ | Tubular trough for fully sealed conveyance. Ideal for airtight conveyance, or for dust-creating materials. | ||

| Spiral Elevator | RVES | Vertical lifting, spiral trough type. Space saving and can accommodate drying, cooling, etc. | Forced vibration generated by rotary vibrator (vibration motor). |

| Rubber-Spring Conveyors | HRC | Variable vibration/low bed type; ideal for light weight and low specific gravity particulate materials. | 3-phase induction motor, unbalanced weights, rubber spring resonators. |

| Model | Vibration- neutralizing effect (*1) |

Stroke (mm) |

Vibration frequency (Hz) |

Max. Trough length (*2) |

Explosion proof construction |

|

|---|---|---|---|---|---|---|

| BM Conveyors | BM | 5 (1) | 10~20 | 6.7~10.8 | 120 | Floor Mounted Type |

| Balanced Conveyors | MVCB | 15~20 | 10~20 | 6.7~10.8 | 30 | Floor Mounted Type |

| MV Conveyors | MVC | (Reference) 100 | 10~20 | 6.7~10.8 | 80 | Floor Mounted Type |

| RV Conveyors | RVF | 10~15 | 2~4 4~6 5~8 |

24.2~29.2 15.8~19.2 12~14.2 |

6 | Floor Mounted Type Suspension Type |

| RVF-φ | ||||||

| Spiral Elevator | RVES | 15~20 | 2~4 4~6 5~10 20~25 |

24.2~29.2 15.8~19.2 12~14.2 8.2~9.8 |

16 (Lifting height) | Floor Mounted Type |

| Rubber-Spring Conveyors | HRC | 5~10 | 5~12 | 15.8~17.5 | 6 | Floor Mounted Type |

*1. Vibration-neutralizing effect of MV conveyors taken as index of 100, and indices for other models based on comparisons with MV conveyors. Index of (1) for BM model applies when conveyor is mounted on vibration damping springs.

*2. Max. trough length may vary with different trough widths. More information available on request.

Comparison of vibrating and other conveyors

| Work objects |

Screw Conveyors |

Bucket Conveyors |

Belt Conveyors |

Vibrating Conveyors |

||

|---|---|---|---|---|---|---|

| Material | Apparent specific gravity (T/m3) (T/m2) |

|||||

| Wet ash | 0.72~0.88 | × | ● | ● | ● | |

| Dry ash | 0.56~0.6 | ● | ● | × | ● | |

| Cement | 1.36~1.6 | ● | ● | ● | ● | |

| Chemicals | Abrasive | - | × | ● | ● | ● |

| Corrosive | - | × | ● | ● | ● | |

| Sticky | - | × | × | × | × | |

| Clay | 0.56~0.88 | ● | × | ● | × | |

| Coal | 0.8 | ● | ● | ● | ● | |

| Coke | 0.64 | × | ● | ● (High-temperature) |

● | |

| Coke ash | 0.48 | × | ● | ● | ● | |

| Cotton seed | 0.4~0.43 | ● | × | ● | ● | |

| Dust | 0.4~0.72 | ● | × | × | ● | |

| Grain | 0.4~0.96 | ● | × | ● | ● | |

| Heavy ores | - | × | ● | ● | ● | |

| Light ores | - | ● | × | ● | ● | |

| Metal powder | - | ● | ● | ● | ● | |

| Rocks/stones | - | × | ● | ● | ● | |

| Salt | 0.72~1.28 | ● | ● | ● | ||

| Sand/gravel | - | × | ● | ● | ● | |

| Sawdust | 0.24~0.32 | ● | × | ● | ● | |

| Soda ash | 0.40~1.05 | ● | × | ● | ● | |

| Soybeans | 0.72 | ● | × | ● | ● | |

| Soybean flour | 0.64 | ● | × | × | ● | |

| Starch | 0.40~0.64 | ● | × | ● | ● | |

| Sugar | 0.88 | ● | × | ● | ● | |

| Sulphur | 0.88~1.0 | ● | × | ● | ● | |

| Compound fertilizer | 0.5~1.3 | × | × | ● | ● | |

| Perphosphoric acid | 1.3 | × | × | ● | ● | |

| Hot materials | - | × | ● | × | ● | |

| Large-sized waste | - | × | × | ● | ● | |

| Kitchen waste | - | × | × | ● | ● | |

Installing Vibrating Conveyors

When installing Vibrating Conveyors, especially MVCB and BM models, in restricted spaces such as in pits, it is necessary to allow room for servicing and maintenance requirements.

The diagram shows suggested installation of an MVCB Balanced Conveyor.

- Please consult us on any concerns about vibration pollution.

- Please consult us on any concerns about vibration pollution.

- Recommended thickness of concrete as blow mentioned

Up to MVCB-1050: at least 200mm

Over MVCB-1200: at least 250mm - For dimension D, please refer to dementions of BM Conveyor.

Anchor Bolt

| E | L | M | S |

|---|---|---|---|

| M16 | 240 | 63 | 60 |

| M20 | 300 | 90 | 60 |

Suspending Devices

Wire

In case of long suspending distance

Turn Buckles

Adjustable of little extent

Suspending Hook

In case of short suspension distance

Special Suspension Tools

When the feeder is especially large and turn buckles & suspension hooks are not available in the market

Never tighten the bracket as shown in the illustration figure.