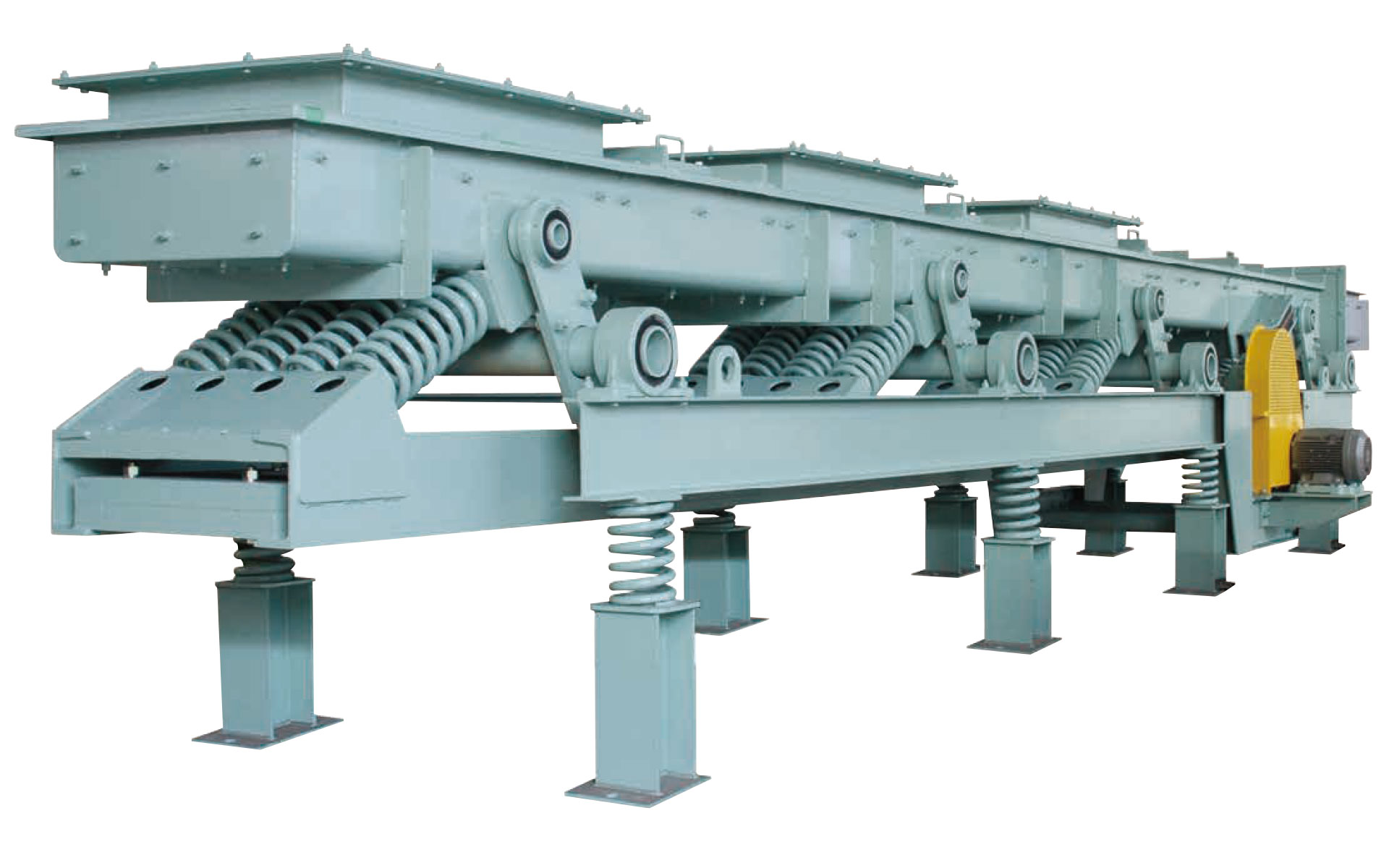

BM Type Balanced Conveyor

High efficiency/Fully balanced

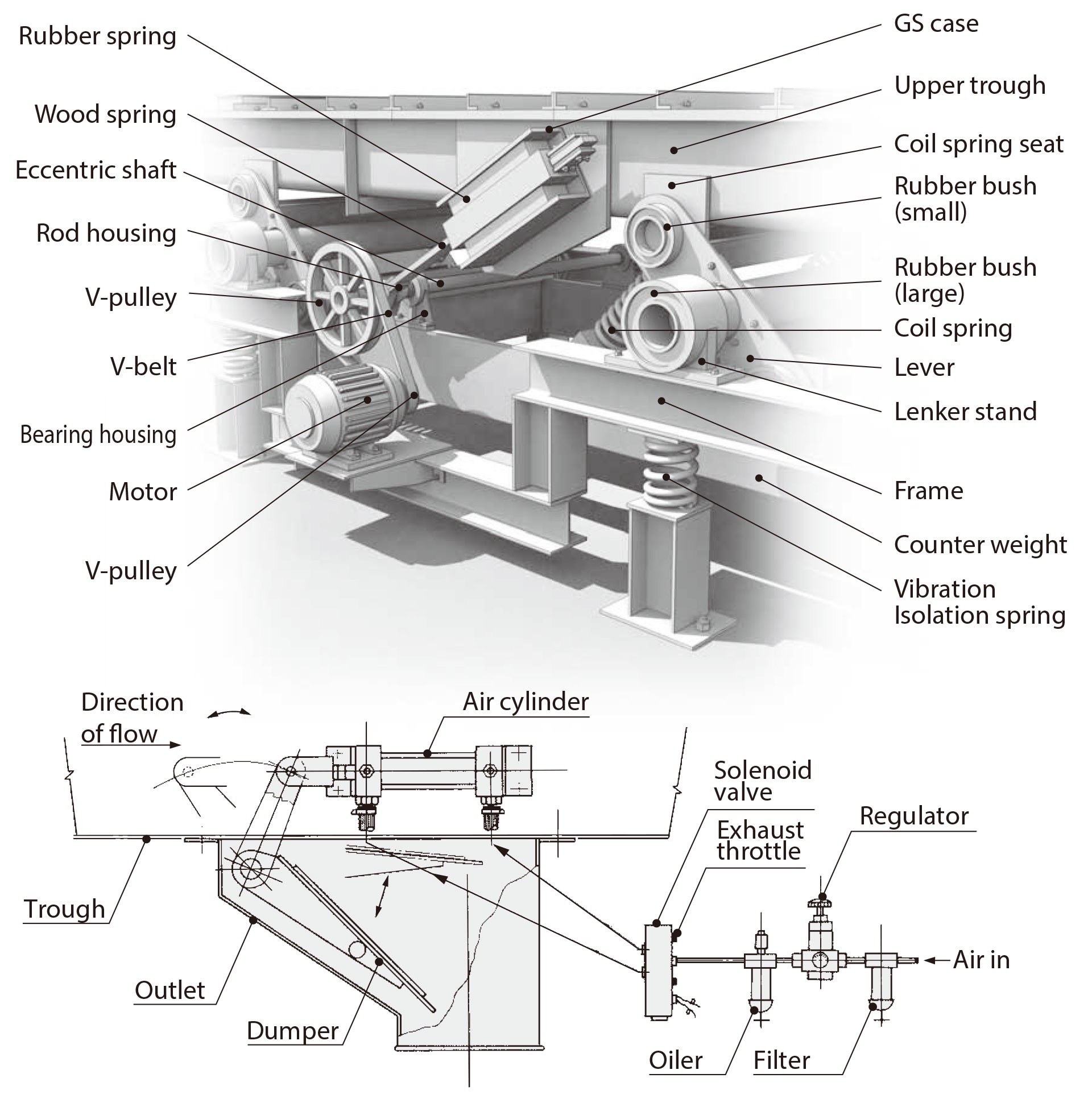

BM conveyors use the fully balanced system. The upper and lower troughs are coupled together by springs, and mounted at the central point of the coupling on a fixed frame. Both troughs are vibrated by means of motor-driven eccentric crank action and spring-generated resonant vibration.

Features

- Safe, vibration-neutralizing construction

The fully balanced design means that no vibration is transmitted to the floor or base. The conveyor is therefore suitable for off-the-floor, or high level installation. When installed on a rigid base such as a concrete floor, the overall height can be reduced by omitting the vibration-damping springs. - Outlets with dumpers

Outlets with dumpers are positioned at various points along the trough to discharge the material as required. Dumpers can be opened and closed automatically or manually. - Adjustment of flow

Flow can be adjusted during transport with a speed control mechanism.

Sealed or long distance transport A cylindrical trough can be used for sealed or long distance conveyance. Sections are connected every 5 or 8 meters to extend trough length. - Upper and lower troughs can be used simultaneously

As a customized one, a trough can be added below the upper trough, enabling two-tiered conveying with the upper and lower troughs to significantly increase conveying capacity. - Upper and lower troughs can be used simultaneously

The lower trough can also be used for conveyance, with the convenience of a lower level inlet and outlet, thus, the efficiency can be boosted by using the two troughs simultaneously.

Structural Diagram

Specifications

Standard Specifications

| Model | Capacity (T/Hr) | Vibration per min (Hz) |

|---|---|---|

| BM-150 | 5 | 6.7~10.8 |

| BM-300 | 20 | 6.7~10.8 |

| BM-450 | 35 | 6.7~10.8 |

| BM-600 | 50 | 6.7~10.8 |

| BM-750 | 65 | 6.7~10.8 |

| BM-900 | 80 | 6.7~10.8 |

| BM-1050 | 95 | 6.7~10.8 |

| BM-1200 | 110 | 6.7~10.8 |

| BM-1350 | 125 | 6.7~10.8 |

| BM-1500 | 140 | 6.7~10.8 |

| BM-1650 | 155 | 6.7~10.8 |

| BM-1800 | 170 | 6.7~10.8 |

| BM-2000 | 185 | 6.7~10.8 |

| Model | Trough length (m) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 18 | 20 | 25 | 30 | ||

| BM-150 | Motor (kW) |

1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 3.7 | 3.7 |

| Gross weight (kg) |

600 | 780 | 960 | 1100 | 1410 | 1590 | 1870 | 2240 | 2700 | 3330 | 4130 | 5440 | |

| BM-300 | Motor (kW) |

1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 | 3.7 | 5.5 |

| Gross weight (kg) |

710 | 930 | 1200 | 1320 | 1700 | 1920 | 2360 | 2970 | 3540 | 4230 | 5100 | 6730 | |

| BM-450 | Motor (kW) |

2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 | 3.7 | 5.5 | 5.5 |

| Gross weight (kg) |

930 | 1180 | 1420 | 1540 | 1970 | 2220 | 2760 | 3250 | 3900 | 4620 | 5740 | 7300 | |

| BM-600 | Motor (kW) |

2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 7.5 |

| Gross weight (kg) |

1050 | 1330 | 1620 | 1760 | 2240 | 2680 | 3100 | 3750 | 4600 | 5400 | 6700 | 8450 | |

| BM-750 | Motor (kW) |

2.2 | 2.2 | 3.7 | 3.7 | 3.7 | 3.7 | 3.7 | 5.5 | 7.5 | 7.5 | 5.5×2 | 5.5×2 |

| Gross weight (kg) |

1350 | 1750 | 2300 | 2500 | 3150 | 3540 | 4150 | 5100 | 6300 | 7260 | 8800 | 11000 | |

| BM-900 | Motor (kW) |

2.2 | 2.2 | 3.7 | 3.7 | 3.7 | 3.7 | 5.5 | 7.5 | 7.5 | 7.5 | 5.5×2 | 7.5×2 |

| Gross weight (kg) |

1450 | 1880 | 2450 | 2680 | 3400 | 3780 | 4580 | 5280 | 6750 | 7900 | 9400 | 11850 | |

| BM-1050 | Motor (kW) |

2.2 | 3.7 | 3.7 | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 5.5×2 | 5.5×2 | 7.5×2 | 7.5×2 |

| Gross weight (kg) |

1640 | 2300 | 2820 | 3050 | 3820 | 4450 | 5200 | 6400 | 7730 | 8800 | 10800 | 13400 | |

| BM-1200 | Motor (kW) |

2.2 | 3.7 | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 7.5 | 5.5×2 | 5.5×2 | 7.5×2 | 11×2 |

| Gross weight (kg) |

1750 | 2430 | 2970 | 3230 | 4170 | 4680 | 5780 | 7000 | 8250 | 9400 | 11500 | 14400 | |

| BM-1350 | Motor (kW) |

3.7 | 3.7 | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 5.5×2 | 5.5×2 | 7.5×2 | 7.5×2 | 11×2 |

| Gross weight (kg) |

2000 | 2580 | 3180 | 3460 | 4440 | 4970 | 6050 | 7350 | 8800 | 10100 | 12300 | 15300 | |

| BM-1500 | Motor (kW) |

3.7 | 3.7 | 3.7 | 3.7 | 5.5 | 7.5 | 7.5 | 5.5×2 | 7.5×2 | 7.5×2 | 7.5×2 | 11×2 |

| Gross weight (kg) |

2100 | 2720 | 3350 | 3630 | 4650 | 5350 | 6300 | 7750 | 9450 | 10700 | 12900 | 16000 | |

| BM-1650 | Motor (kW) |

3.7 | 3.7 | 3.7 | 5.5 | 7.5 | 7.5 | 5.5×2 | 5.5×2 | 7.5×2 | 7.5×2 | 11×2 | 11×2 |

| Gross weight (kg) |

2560 | 3400 | 4200 | 4680 | 6050 | 6670 | 8000 | 10400 | 12700 | 14000 | 17200 | 22000 | |

| BM-1800 | Motor (kW) |

3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 7.5 | 5.5×2 | 5.5×2 | 7.5×2 | 7.5×2 | 11×2 | 11×2 |

| Gross weight (kg) |

2680 | 3550 | 4550 | 4900 | 6350 | 6950 | 8400 | 10850 | 13250 | 14600 | 17800 | 22900 | |

| BM-2000 | Motor (kW) |

3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 7.5 | 5.5×2 | 7.5×2 | 7.5×2 | 11×2 | 11×2 | 11×2 |

| Gross weight (kg) |

2840 | 3760 | 4760 | 5230 | 6780 | 7680 | 9020 | 11750 | 14200 | 15800 | 19200 | 24500 | |

1. Max capacity is for conveying sand (apparent bulk density 1.5, moisture content 4-6%) in a horizontal trough.

2. Motor capacity and gross weight may vary according to the handling material type, and use of liner.

3. Motor capacity and gross weight assume use of liner without cover.

Outer Dimensions

Dimension Table

Unit: mm

| Model | B | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BM-150 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | 18000 | 20000 | 25000 | 30000 |

| BM-300 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | 18000 | 20000 | 25000 | 30000 |

| BM-450 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | 18000 | 20000 | 25000 | 30000 |

| BM-600 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | 18000 | 20000 | 25000 | 30000 |

| BM-750 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | 18000 | 20000 | 25000 | 30000 |

| BM-900 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | 18000 | 20000 | 25000 | 30000 |

| BM-1050 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | 18000 | 20000 | 25000 | 30000 |

| BM-1200 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | 18000 | 20000 | 25000 | 30000 |

| BM-1350 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | 18000 | 20000 | 25000 | 30000 |

| BM-1500 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | 18000 | 20000 | 25000 | 30000 |

| BM-1650 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | 18000 | 20000 | 25000 | 30000 |

| BM-1800 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | 18000 | 20000 | 25000 | 30000 |

| BM-2000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | 18000 | 20000 | 25000 | 30000 |

| Model | A | C | D | E |

|---|---|---|---|---|

| BM-150 | 150 | 140 | 550 | 700 |

| BM-300 | 300 | 200 | 700 | 800 |

| BM-450 | 450 | 200 | 850 | 800 |

| BM-600 | 600 | 250 | 1000 | 900 |

| BM-750 | 750 | 250 | 1150 | 900 |

| BM-900 | 900 | 250 | 1300 | 900 |

| BM-1050 | 1050 | 250 | 1450 | 1000 |

| BM-1200 | 1200 | 250 | 1600 | 1000 |

| BM-1350 | 1350 | 250 | 1750 | 1000 |

| BM-1500 | 1500 | 250 | 1900 | 1000 |

| BM-1650 | 1650 | 250 | 2150 | 1000 |

| BM-1800 | 1800 | 250 | 2300 | 1000 |

| BM-2000 | 2000 | 250 | 2500 | 1000 |

Measure "E" for reference.