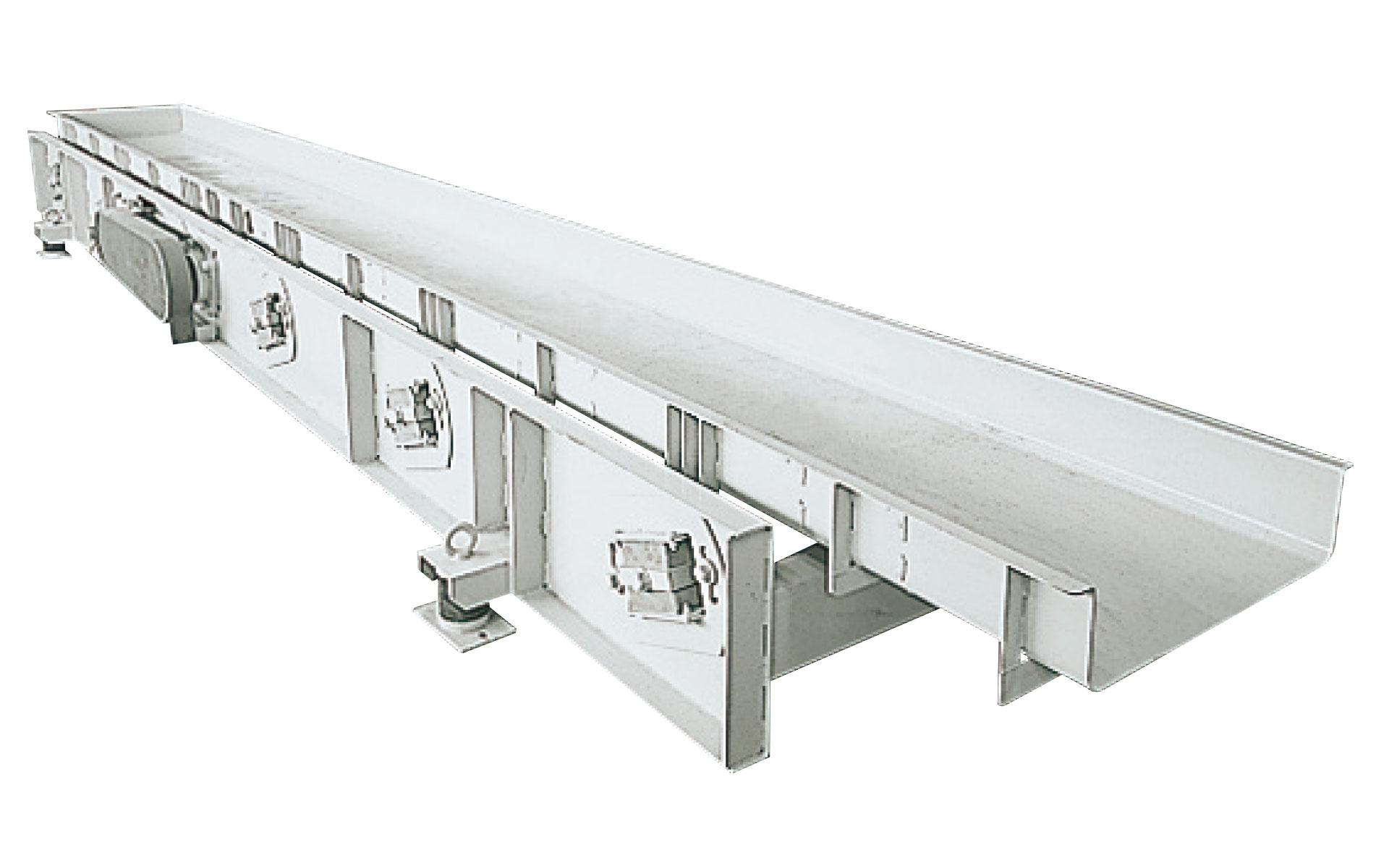

Rubber-Spring Conveyo HRC

Variable vibration angle/low bed

Rubber spring conveyors are low-bed conveyors in which the trough angle of

vibration can be freely adjusted to match the material and its conveyance requirements, which was difficult for conventionals.

Circular vibration is generated by an unbalanced weight driven by a motor, and is amplified by means of resonating rubber springs with variable angles of vibration, to provide uniform, stable vibration throughout the trough.

Features

- Vibration angle can be adapted to match material

In contrast to former conveyors, the angle of the vibration-resonating rubber springs can be easily adjusted to provide the ideal vibration for the type of material to be transported. - Small size but large capacity

With increased vibration frequency (max.17.5Hz/sec) and a variable angle of vibration, the HRC model offers greater vibration magnitude (max.12mm), and therefore has double the conveyance capacity of former vibrating conveyors. This high performance conveyor is therefore able to move volumes never previously possible with such small-sized equipment. - Easy picking operation

The trough amplitude and transfer speed can be easily adjusted for optimum vibration transfer with minimal material movement during picking operations, thereby reducing eye fatigue. - Low height/low floor type

The lightweight shaped steel base frame is effectively connected to the trough by specially designed rubber springs, which results in a low floor type with a low overall body height. - Vibration dampers reduce noise

The use of vibration resonators means that a small vibration source can produce a large vibrating effect. Vibration of the frame is minimal, and the frame is itself mounted on vibration-absorbing springs. Thus, only the tiniest degree of vibration is transmitted to the floor or base, and operation of the conveyor creates very little noise. - Easy maintenance and inspection

n addition to the simple structure, all parts such as rubber springs and bearings are individually attached from the outside, allowing easy maintenance, inspection, and parts replacement. - Fully adaptable for low or high speed conveyance

A special control mechanism allows free adjustment of trough vibration frequency, giving an unlimited choice within a wide range of conveyance speeds.

Structural diagram

Specifications

Standard Specifications

| Model | Capacity (T/Hr) |

Vibration per min (Hz) |

Trough length (m) | ||||

|---|---|---|---|---|---|---|---|

| 3 | 4 | 5 | 6 | ||||

| HRC 200 | 10 | 15.8~17.5 | Motor (kW) |

0.75 | 0.75 | 1.5 | 1.5 |

| Gross weight (kg) |

300 | 400 | 500 | 600 | |||

| HRC 300 | 15 | 15.8~17.5 | Motor (kW) |

0.75 | 1.5 | 1.5 | 1.5 |

| Gross weight (kg) |

350 | 450 | 550 | 650 | |||

| HRC 450 | 20 | 15.8~17.5 | Motor (kW) |

1.5 | 1.5 | 1.5 | 2.2 |

| Gross weight (kg) |

450 | 550 | 650 | 850 | |||

| HRC 600 | 30 | 15.8~17.5 | Motor (kW) |

1.5 | 1.5 | 2.2 | 2.2 |

| Gross weight (kg) |

600 | 700 | 900 | 1050 | |||

| HRC 750 | 40 | 15.8~17.5 | Motor (kW) |

2.2 | 2.2 | 3.7 | 3.7 |

| Gross weight (kg) |

700 | 900 | 1100 | 1350 | |||

| HRC 900 | 50 | 15.8~17.5 | Motor (kW) |

2.2 | 3.7 | 3.7 | 3.7 |

| Gross weight (kg) |

900 | 1100 | 1300 | 1500 | |||

1. Standard trough is open, without cover or liner.

2. Capacity is for conveying granulated sugar (apparent specific gravity 0.8, moisture content 0.05%) in a horizontal trough.

3. Motor capacity and overall weight may vary depending on type of material conveyed, and use of cover or liner.

Outer Dimensions

Dimension Table

Unit: mm

| Model | A | B | C | D | E | E' | F | G |

|---|---|---|---|---|---|---|---|---|

| HRC 200-3 | 200 | 3000 | 150 | 380 | - | 270 | 450 | 400 |

| HRC 200-4 | 200 | 4000 | 150 | 380 | 520 | - | 400 | 400 |

| HRC 200-5 | 200 | 5000 | 150 | 380 | 520 |

- |

400 | 400 |

| HRC 200-6 | 200 | 6000 | 150 | 380 | 520 |

- |

400 | 400 |

| HRC 300-3 | 300 | 3000 | 150 | 480 | - | 370 | 450 | 400 |

| HRC 300-4 | 300 | 4000 | 150 | 480 | 620 |

- |

400 | 400 |

| HRC 300-5 | 300 | 5000 | 150 | 480 | 620 |

- |

400 | 400 |

| HRC 300-6 | 300 | 6000 | 200 | 480 | 620 |

- |

400 | 400 |

| HRC 450-3 | 450 | 3000 | 150 | 655 | - | 550 | 480 | 450 |

| HRC 450-4 | 450 | 4000 | 150 | 655 | 800 |

- |

400 | 450 |

| HRC 450-5 | 450 | 5000 | 180 | 655 | 850 |

- |

400 |

450 |

| HRC 450-6 | 450 | 6000 | 200 | 700 | 900 |

- |

400 |

450 |

| HRC 600-3 | 600 | 3000 | 180 | 850 | - | 700 | 620 | 500 |

| HRC 600-4 | 600 | 4000 | 180 | 850 | 1050 |

- |

430 | 500 |

| HRC 600-5 | 600 | 5000 | 180 | 850 | 1050 |

- |

430 |

500 |

| HRC 600-6 | 600 | 6000 | 220 | 850 | 1050 |

- |

430 |

500 |

| HRC 750-3 | 750 | 3000 | 200 | 1010 | - | 850 | 620 | 500 |

| HRC 750-4 | 750 | 4000 | 200 | 1010 | 1200 |

- |

450 | 500 |

| HRC 750-5 | 750 | 5000 | 200 | 1010 | 1200 |

- |

450 | 500 |

| HRC 750-6 | 750 | 6000 | 250 | 1010 | 1200 |

- |

450 | 500 |

| HRC 900-3 | 900 | 3000 | 200 | 1165 | - | 1000 | 620 | 500 |

| HRC 900-4 | 900 | 4000 | 200 | 1165 | 1350 |

- |

450 | 500 |

| HRC 900-5 | 900 | 5000 | 200 | 1165 |

1350 |

- |

450 | 500 |

| HRC 900-6 | 900 | 6000 | 250 | 1165 |

1350 |

- |

450 | 500 |