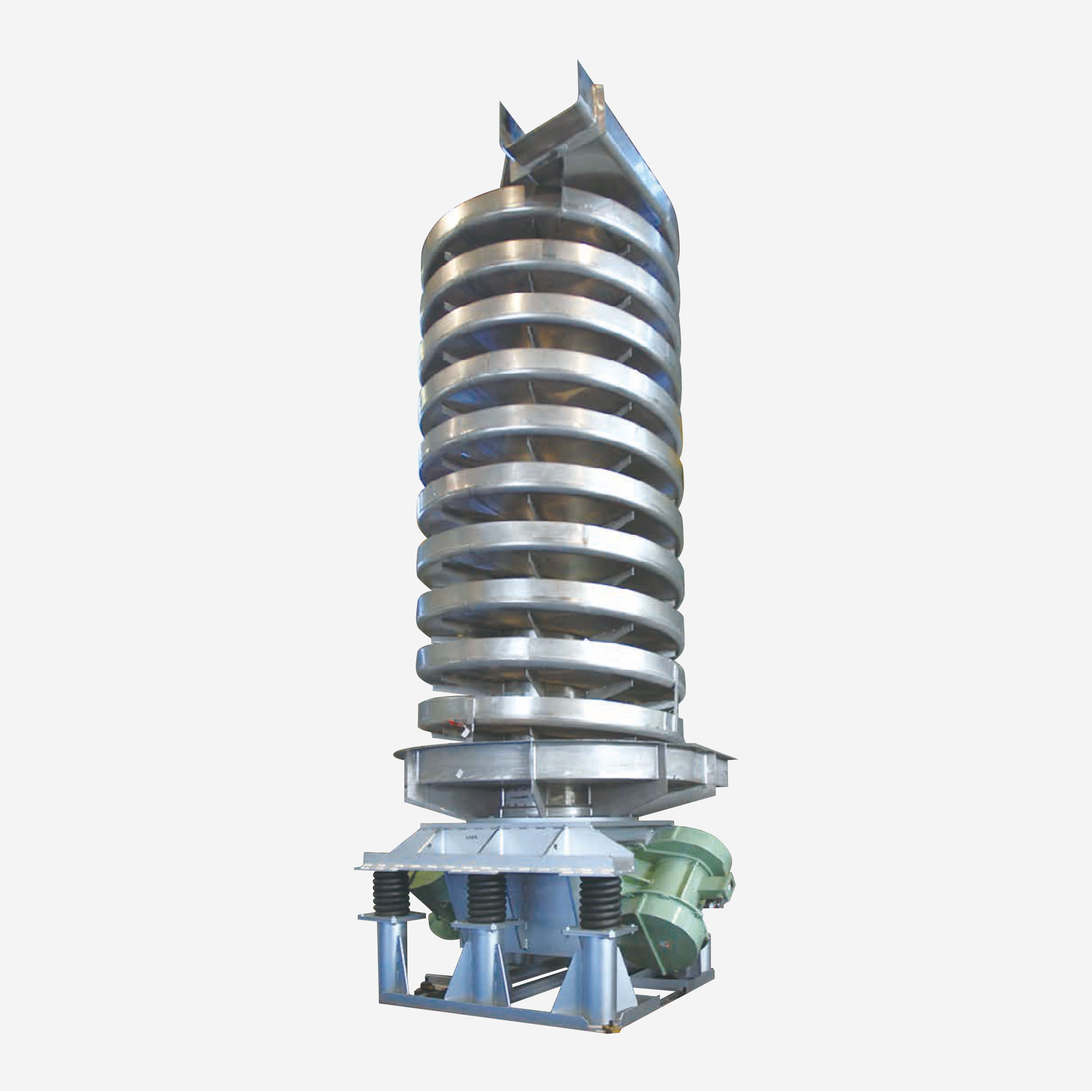

Spiral Elevator RVES

Space saving/Vertical lift

Spiral elevator combines a drive mechanism and a vertically aligned, spiral-shaped trough, which vibrates to drive particulate materials to the top. Suitable for all types of materials, it can also be used for downward conveyance. Simultaneous drying and cooling processes can be accommodated.

Features

- Minimal installation area

The vertical structure minimizes the installation area and space occupied by the trough, and the surface area of the trough can be widely used. - Available in cooling and drying structure

When cooling and drying are required, cooling and drying can be sufficiently performed by natural or forced ventilation due to temperature differences, by staying the material to be conveyed for a long time, or by reversing the material. - Smooth conveyance

Ideal for materials difficult to handle with a bucket or belt conveyor, as well as spherical particles. - Capable of fixed-quantity transfer

Constant material transfer speed allows for continuous conveying of a fixed amount of material. - Flow easily adjustable

The flow of material can be easily controlled by adjusting the unbalanced weight of the rotary vibrator. - No dust

Even materials with very small apparent specific gravity and scattering hardly generate dust during conveyance. - Special structure

In the case of a totally enclosed dustproof structure, a special structure with a clear cover can be installed to inspect the product during conveyance. - Easy maintenance

The drive mechanism is compact, and maintenance is easy because there is no need to worry about trough wear.

Specifications

Standard Specifications

| Model | Capacity (T/Hr) |

Rotary vibrating motor specification | Lift (m) |

Gross weight (kg) |

Applicable controller |

|||

|---|---|---|---|---|---|---|---|---|

| Model | Capacity (kw) |

No. of poles (P) |

No. of motor (number of units) |

|||||

| RVES-500-1.5 | 2.5 | RV-44D | 0.4 | 4 | 2 | 1.5 | 300 | ORV-44×2R |

| RVES-650-3 | 4 | RV-78B | 0.75 | 8 | 2 | 3 | 650 | ORV-78×2R |

| RVES-780-4.5 | 5 | RV-158B | 1.5 | 8 | 2 | 4.5 | 1000 | ORV-158×2R |

| RVES-860-6 | 6 | RV-228B | 2.2 | 8 | 2 | 6 | 1500 |

ORV-228×2R |

| RVES-1000-7.5 | 8 | RV-378B | 3.7 | 8 | 2 | 7.5 | 2000 | ORV-378×2R |

| RVES-1200-8.5 | 10 | RV-558B | 5.5 | 8 | 2 | 8.5 | 3000 | ORV-558×2R |

| RVES-1500-10 | 12 |

RV-758B |

7.5 | 8 | 2 | 10 | 4000 |

ORV-758×2R |

| RVES-2000-5.6 | 20 | RV-5512B | 5.5 | 12 | 2 | 5.6 | 8000 | - |

Max capacity is for conveying sand (apparent bulk density 1.5, moisture content 4-6%) in a horizontal trough.

Outer Dimensions

Dimension Table

Unit: mm

| Model | A | B | C | D | E | F | N-Z | G |

|---|---|---|---|---|---|---|---|---|

| RVES-500-1.5 | 500 | 750 | 280 | 50 | 600 | 610 | 4-15 | 268 |

| RVES-650-3 | 650 | 1000 | 350 | 80 | 900 | 880 | 4-15 | 318 |

| RVES-780-4.5 | 780 | 1100 | 420 | 100 | 1100 | 950 | 8-15 | 406 |

| RVES-860-6 | 860 | 1200 | 450 | 120 | 1300 | 1100 | 8-18 | 457 |

| RVES-1000-7.5 | 1000 | 1400 | 550 | 150 | 1500 | 1350 | 8-18 | 508 |

| RVES-1200-8.5 | 1200 | 1600 | 670 | 170 | 1700 | 1400 | 10-18 | 610 |

| RVES-1500-10 | 1500 | 2000 | 800 | 200 | 2000 | 1450 | 10-18 | 711 |

| RVES-2000-5.6 | 2000 | 2600 | 1400 | 300 | 2500 | 1800 | 14-23 | 1000 |