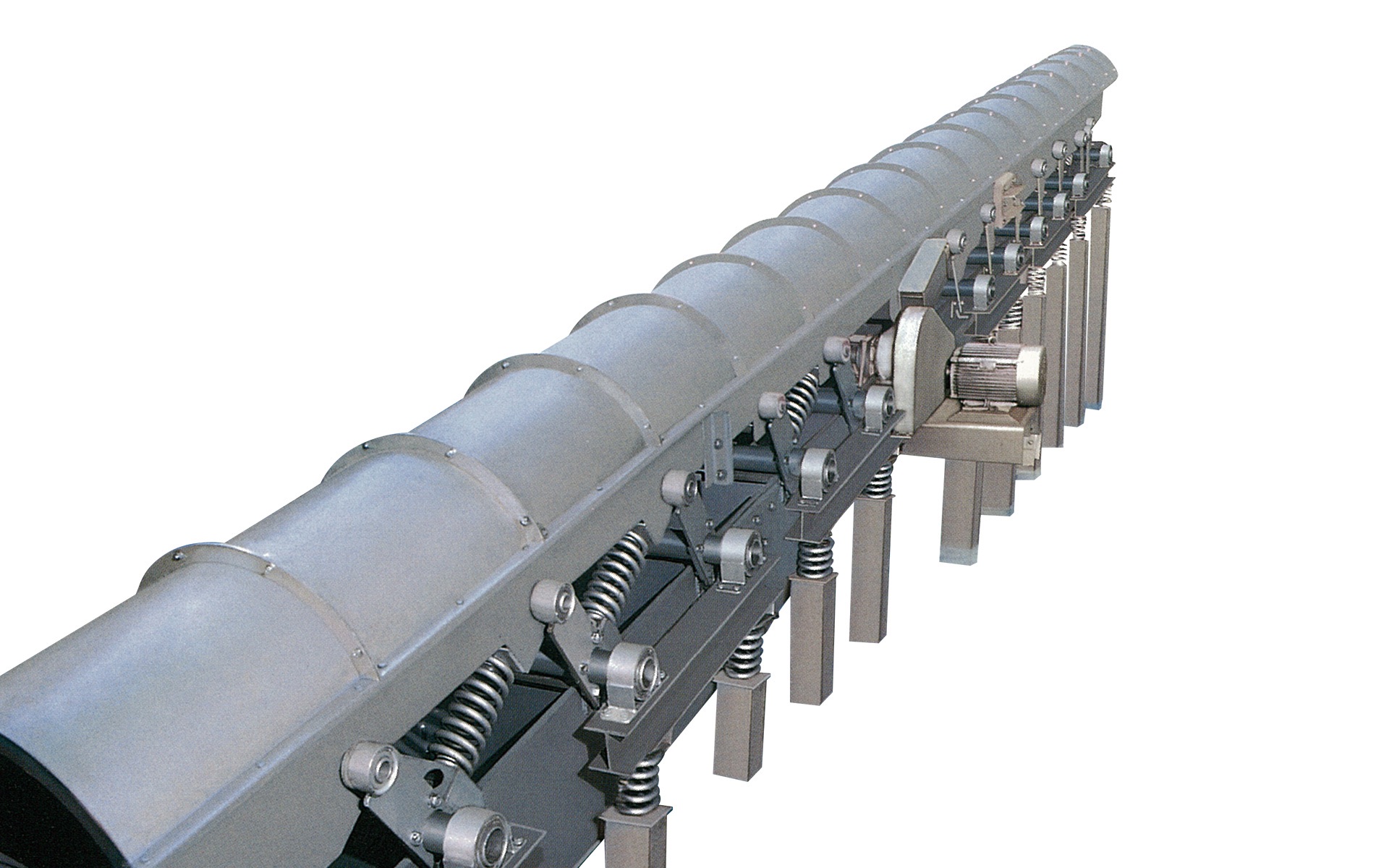

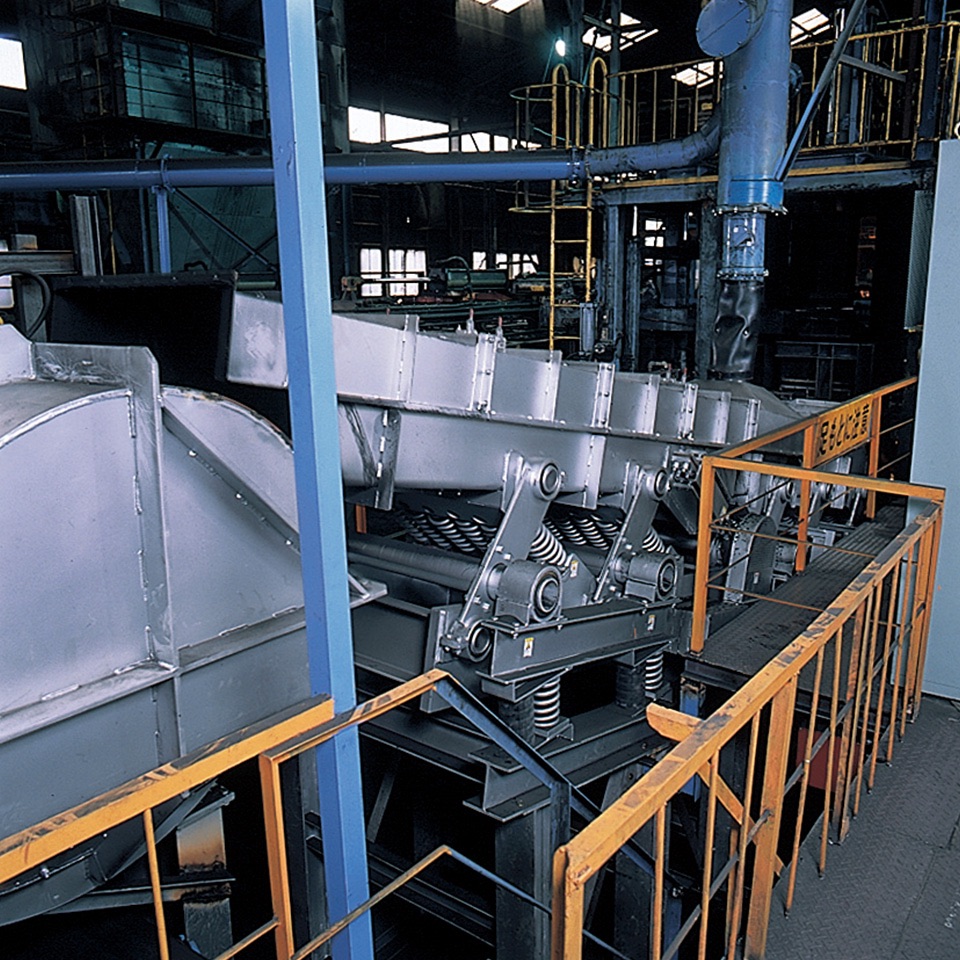

Slope Conveyor

Going up by vibration. The latest vibrating conveyor replaces belt conveyor

The latest vibration conveyor is now available. The name is "Slope Conveyor". This conveyor uses a unique technology to realize upward conveyance, which has been difficult to achieve with conventional vibrating conveyors, and it efficiently achieves upward vibrating conveyance at an inclination angle of Max. 18 degrees by taking advantage of the features of vibrating conveyors, which are highly effective in conveying granular materials.

It can be used in a wide range of fields, from food and chemical to foundry, and has replaced the belt conveyor used until now, solving problems such as the work environment and maintenance.

Features

- Enclosed structure improves the working environment

The enclosed structure can be widely used as an alternative to belt conveyors and apron conveyors, and the working environment can be greatly improved by eliminating material spills and splashing.

It also prevents foreign matter from mixing with the material to be conveyed, resulting in a significant effect on quality improvement. - Durable and maintenance-free

Especially in the casting industry, high heat can cause belt breakage due to burrs and sand spills due to sand adhesion. Slope conveyors, however, have none of these problems and are extremely easy to maintain. - Easy line connection

Long-distance conveying is possible, and the system can be easily connected to material feeders, vibrating conveyors for post-processing, screens, etc., to streamline the process.

In addition, material damage and dust problems caused by falling material at the "transfer points" of belt conveyors and apron conveyors can be eliminated. - Conveying solids and adhesive materials

In addition to conveying granular materials, solids such as cast products can also be conveyed by combining them with sand and other granular materials.

The use of a special liner and high-amplitude drive system enables efficient conveyance of adhesive materials as well.

Conveying Capacity

| Trough width (mm) | Inclination angle 18 |

|---|---|

| 450 | 12 |

| 600 | 16 |

| 750 | 20 |

| 900 | 24 |

| 1050 | 28 |

Dimensions

Dimension Table

Unit: mm

| Format | Width A | Length B | C | D | H | E (Max) | |||

|---|---|---|---|---|---|---|---|---|---|

| Motor (kW) is shown in ( ) in the lower row | |||||||||

| BM-450 | 450 | 5000 (5.5) |

10000 (3.7×2) |

15000 (5.5×2) |

20000 (5.5×2) |

200 | 950 | 1300 | 950 |

| BM-600 | 600 | 5000 (5.5) |

10000 (5.5×2) |

15000 (5.5×2) |

20000 (7.5×2) |

250 | 1100 | 1350 | 1100 |

| BM-750 | 750 | 750 (3.7×2) |

10000 (5.5×2) |

15000 (7.5×2) |

20000 (11×2) |

250 | 1250 | 1350 | 1250 |

| BM-900 | 900 | 900 (3.7×2) |

10000 (5.5×2) |

15000 (7.5×2) |

20000 (11×2) |

250 | 1400 | 1350 | 1300 |

| BM-1050 | 1050 | 1050 (7.2×2) |

10000 (7.5×2) |

15000 (11×2) |

- | 250 | 1550 | 1350 | 1400 |