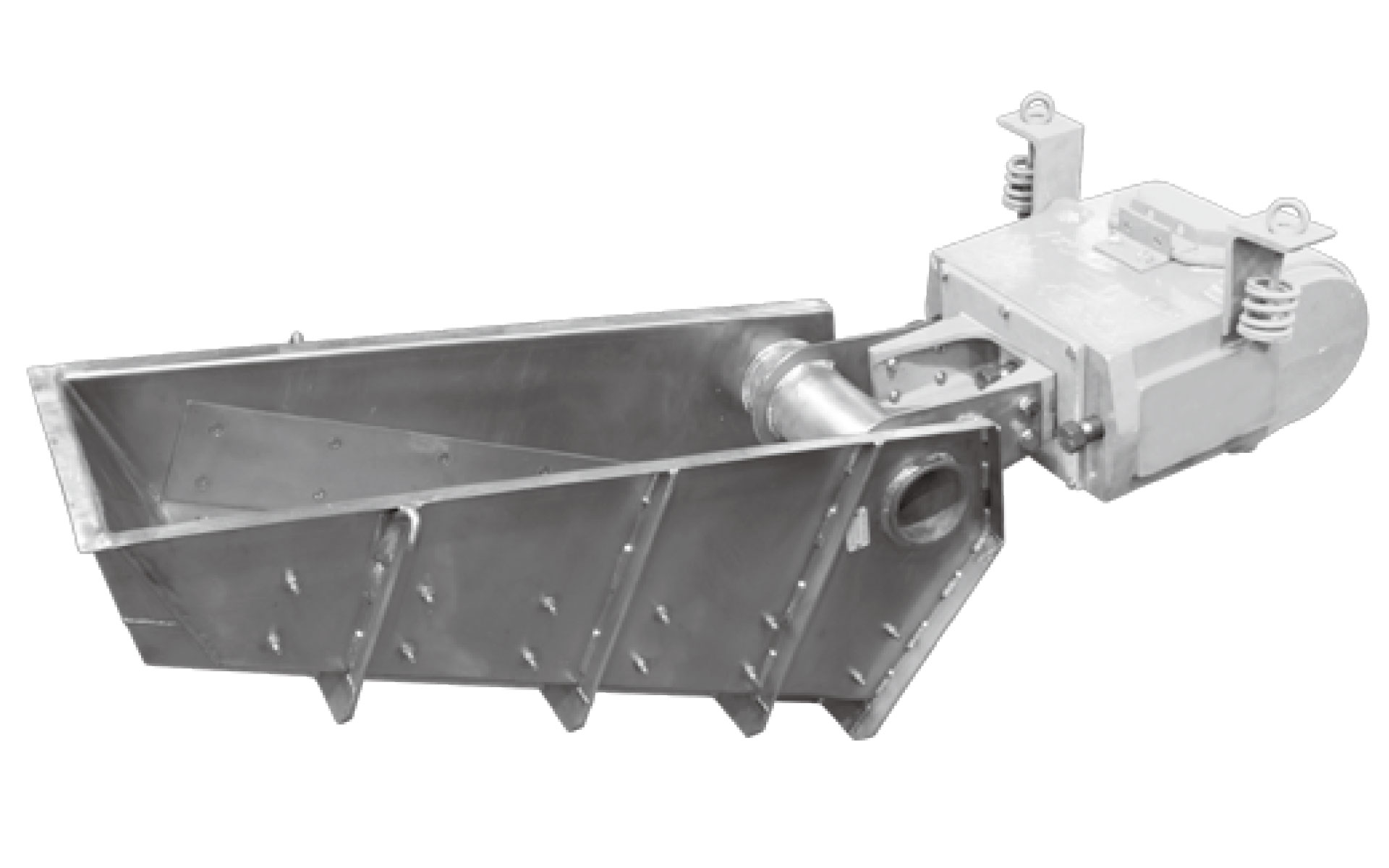

CF/F Type Electromagnetic Feeders

Multipurpose type from fine powder to large lumps

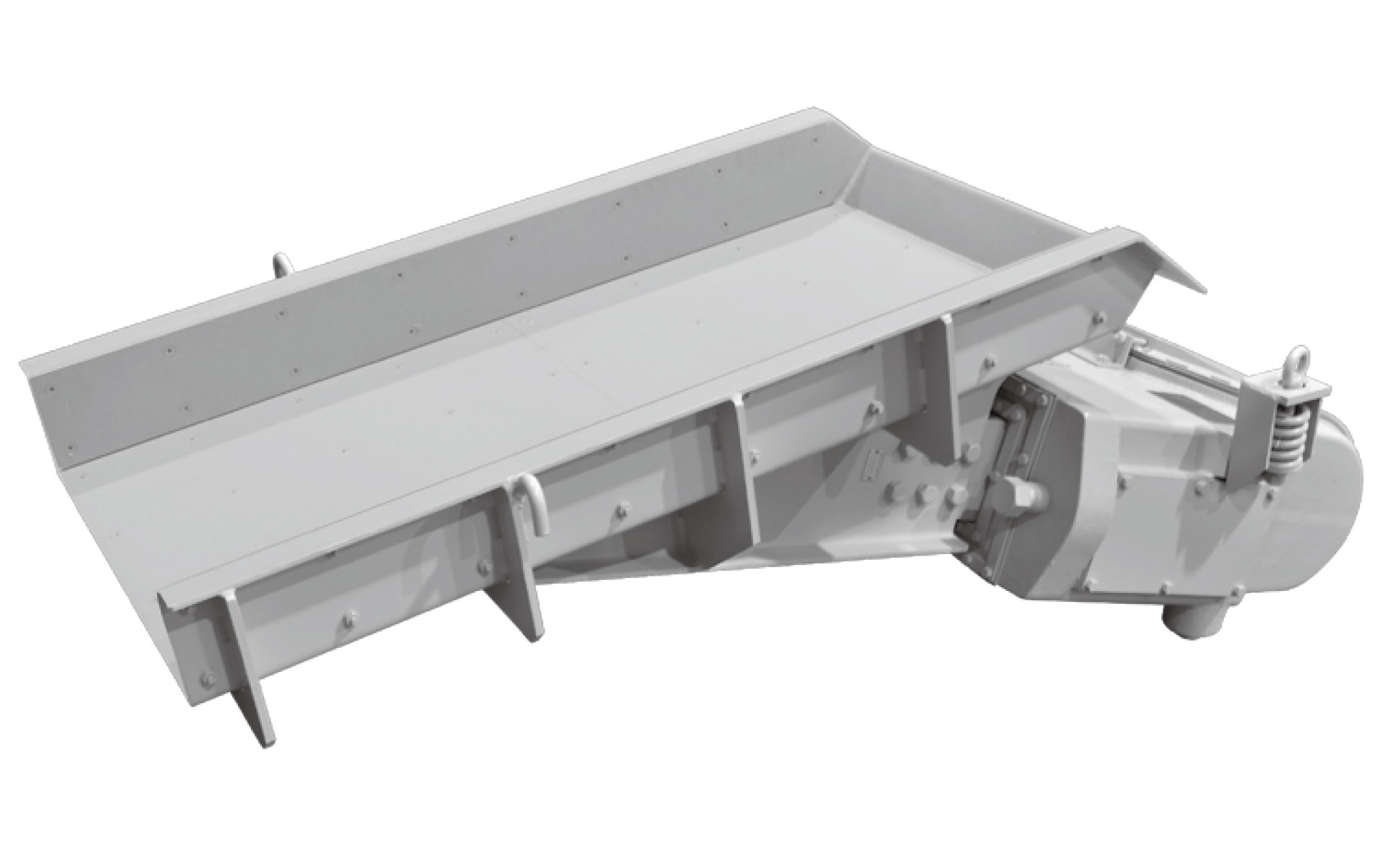

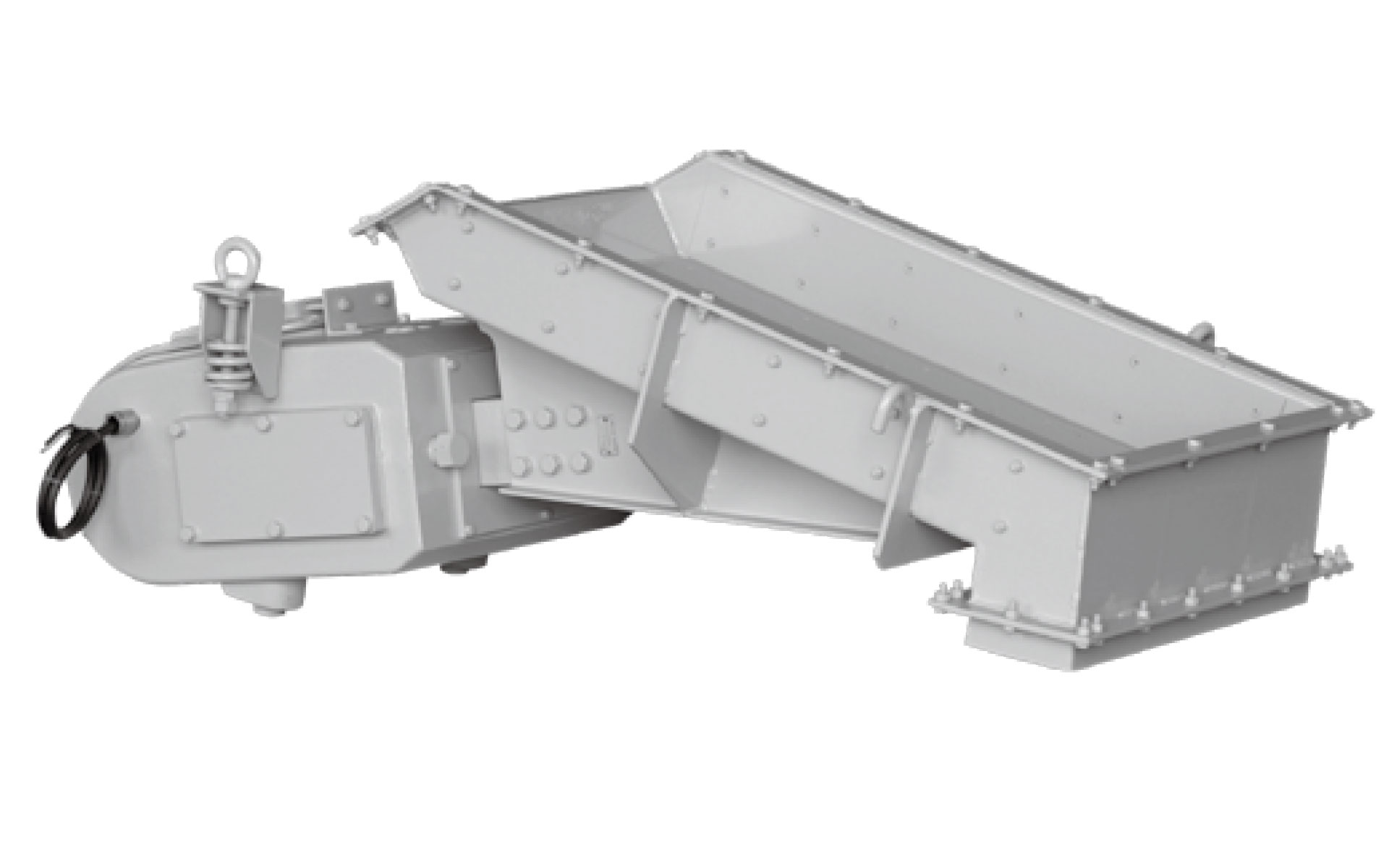

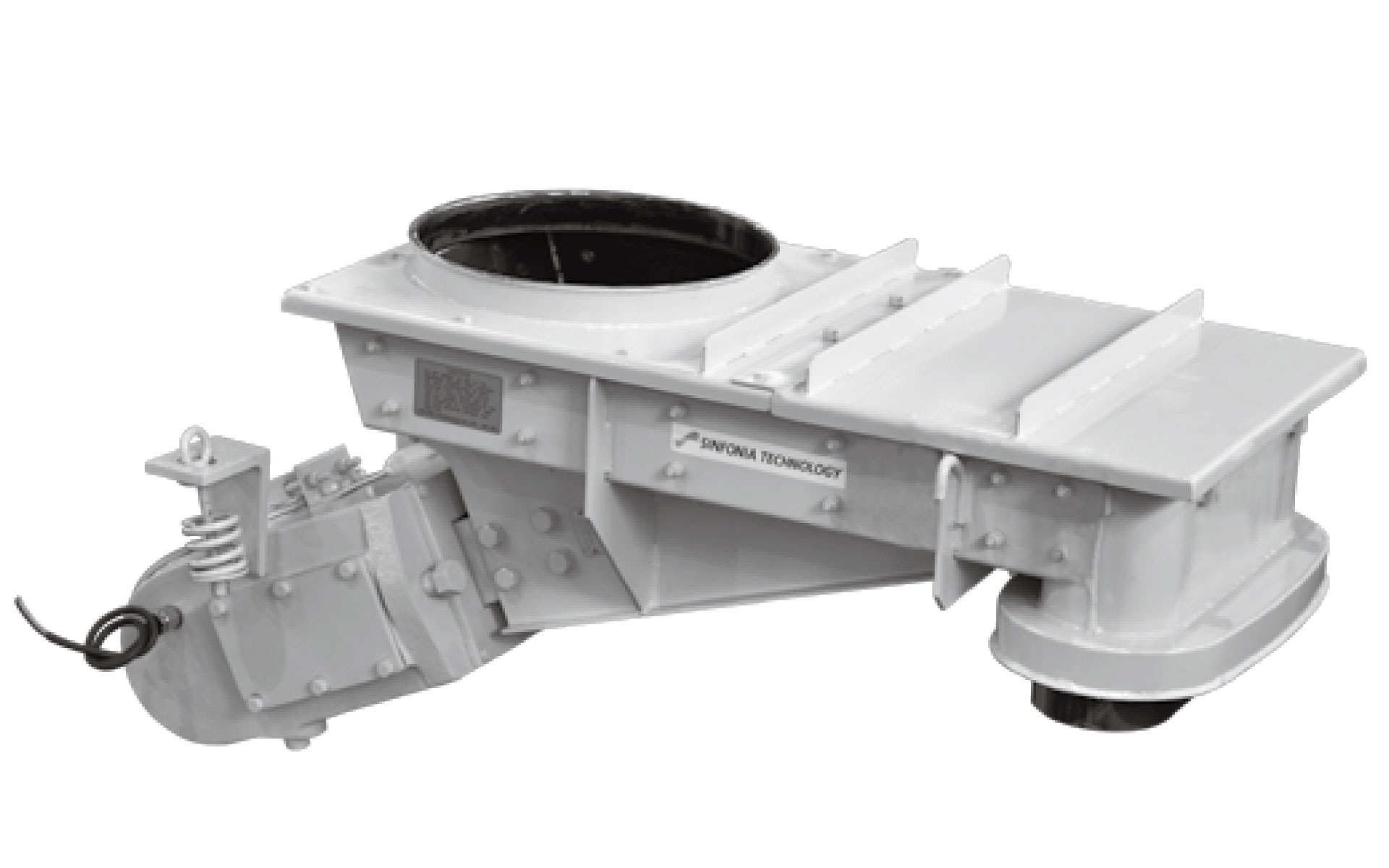

Electromagnetic feeders utilize the conveying phenomenon of electromagnetic vibration and are the most effective feeders for cutting and feeding all types of materials, from fine powders to large lumps. The F type electromagnetic feeder comes in two types: the standard type, in which the electromagnetic drive is mounted at the rear bottom of the trough, and the upper drive type, in which it is mounted at the front top.

F-152BDT or higher model

CF-1/2/3/4

F-152BDT or higher model

Structural diagram

F-152BDT~F-88BDT

Both suspension type and floor-mounted type are installable.

The trough and the drive unit are hold by suspension device (if you use a suspension type) or supporting device (if you use a floor mounted type).

Specifications

Standard Specifications

| Model | Max. feeding capacity (T/Hr) |

Trough size width ×length (mm) |

Voltage (V) |

Frequency (Hz) |

Vibration per min. |

Input (W) |

Current (A) |

Voltage × current (VA) |

Rating | Weight (kg) |

Applicable controller |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sand | Coal | |||||||||||

| F-152BDT | 10 | - | 200×610 | 200/400 | 50/60 | 3000/3600 | 60 | 1.5/0.7 | 300 | Continuous | 40 | C4-5B C6-15SC C5-15EHF |

| *F-212BDT | 35 | 18 | 310×762 | 200/400 | 50/60 | 3000/3600 | 100 | 2.5/1.25 | 500 | Continuous | 120 | |

| F-22BDT | 50 | 26 | 356×914 | 200/400 | 50/60 | 3000/3600 | 200 | 5/2.5 | 1000 | Continuous | 200 | |

| *FH-22BDT | 65 | 34 | 458×914 | 200/400 | 50/60 | 3000/3600 | 280 | 7/3.5 | 1400 | Continuous | 230 | C6-15SC C5-15EHF |

| F-33BDT | 100 | 52 | 558×1067 | 200/400 | 50/60 | 3000/3600 | 400 | 10/5 | 2000 | Continuous | 460 | |

| *FH-33BDT | 130 | 68 | 610×1067 | 200/400 | 50/60 | 3000/3600 | 560 | 14/7 | 2800 | Continuous | 560 | |

| F-44BDT | 220 | 115 | 762×1219 | 200/400 | 50/60 | 3000/3600 | 960 | 24/12 | 4800 | Continuous | 1000 | C6-30SC C5-30EHF |

| *F-45BDT | 330 | 172 | 914×1524 | 200/400 | 50/60 | 3000/3600 | 1200 | 30/15 | 6000 | Continuous | 1500 | |

| FH-45BDT | 440 | 230 | 1219×1524 | 200/400 | 50/60 | 3000/3600 | 1440 | 36/18 | 7200 | Continuous | 1800 | C6-50SC C5-50EHF |

| F-55BDT | 600 | 310 | 1372×1524 | 200/400 | 50/60 | 3000/3600 | 2000 | 50/25 | 10000 | Continuous | 3200 | |

| F-66BDT | 800 | 420 | 1524×1829 | 200/400 | 50/60 | 3000/3600 | 2400 | 60/30 | 12000 | Continuous | 3900 | C6-80SC C5-80EHF |

| F-88BDT | 1250 | 650 | 1829×1829 | 200/400 | 50/60 | 3000/3600 | 3200 | 80/40 | 16000 | Continuous | 6500 | |

1. Feeding capacities apply to standard flat-bottom open type with hopper skirts when bulk densities of sand and coal are 1.6 and 0.8, respectively, trough angle is 10° (horizontal for models F00B~11B) and voltage is 60Hz.

2. Asterisked (*) models are also available with explosion-proof structure (eG3) for extra safety.

3. Standard paint color is Munsell 2.5G 7/2

4. Power supply and wire size should be selected based on VA.

5. Weight for CF-1~CF-4 is referred for driving part. Weight for F-152BDT~F-88BDT is referred Flat bottom open type (SS400)