Vibrating Screens

Effective in increasing productivity and quality

Screen with unique vibration

Sinfonia Technology has manufactured a number of excellent vibrating screens using its unique vibration technology and has gained a high level of trust from various fields. Our vibrating screens, which are the result of our severe research on vibration and our experience in delivering various types of vibrating equipment, are used to efficiently and speedily perform screening operations, while simultaneously improving quality and cost reductions.

The ideal screen can be selected.

When selecting a screen, it is necessary to fully consider the shape, properties, and flow rate of the material to be screened, as well as the purpose of the screening, installation conditions, operating conditions, and factory environment. Sinfonia Technology's vibrating screens are manufactured based on years of experience and strict testing, and are available in a wide variety of mesh sizes, capacities, and vibrating types. This allows you to select the optimum screen for your application and purpose, regardless of the conditions of use, and ensures improved productivity.

SF Type Electromagnetic Screen

High-efficiency model with delicate but fast vibration

RVS Type Rotary Vibrating Screen

Powerful screen with direct vibration to trough

Below-deck drive type (Floor-mounted type)

Above-deck drive type (Floor-mounted type)

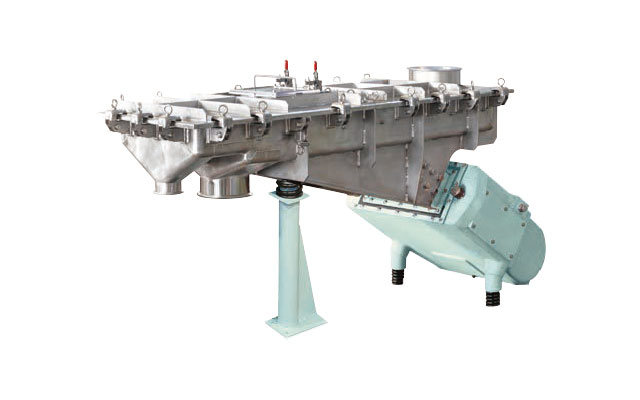

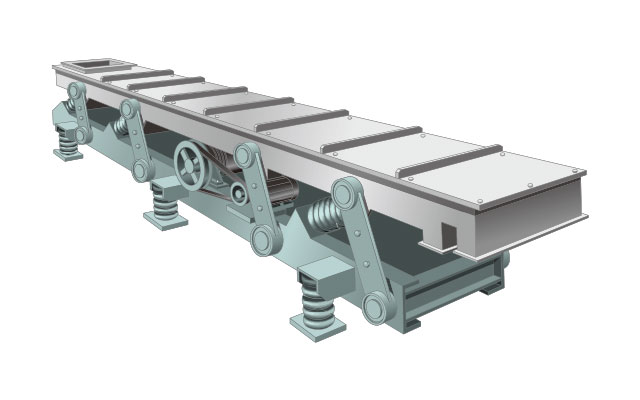

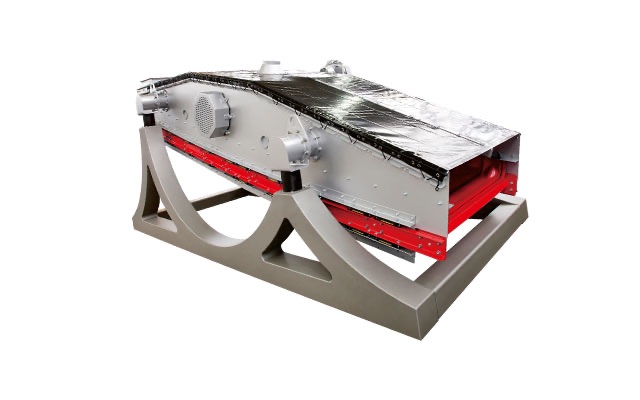

SMVCB Type Balanced Screen

Vibration pollusion free, multi-purpose type

KRL/ED-Single deck-

KRL/DD-Double deck-

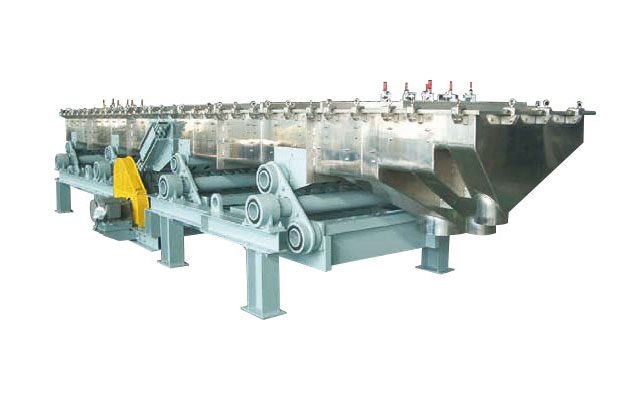

SBM Type Perfect Balanced Screen

Perfect Balanced Screens

KRL/ED-Single deck-

KRL/DD-Double deck-

KRL The Wave Screen

A unique type of screen with a waving screen

Controller

Model List/Features

High efficiency screen suitable for any particular material, application, purpose, etc. irrespective of grain size.

| Model | Applications | Drive method |

|---|---|---|

| SF Type Electromagnetic Screen | Frequently used as screening combined with cutting out function. Also combined and used with weighing machines. Most suitable for removing lumps and wastes of resin pellets, and for fine powders in chemical, food and other industries. | Direct linear drive type using leaf-spring resonance with electromagnetically generateds vibration. |

| RVS Type Rotary Vibrating Screen | Suitable for a wide variety of process in feed, food, chemical, ceramic and other industries. Mainly middle sized materials up to 1800x2000 (mm). | Rotary vibrator is mounted directly on trough for direct transmission of vibrations to trough and screen. |

| SMVCB Type Balanced Screen | Screen used at various types of industries, and having not only screening function but also conveying function. Suitable for screening and conveying molding sand, resin powder, pellet, sugar, abrasives, coal powder, alumina, and more. | Resonant type elastic drive using 3-phase induction motor and eccentric shaft. |

| SBM Type Perfect Balanced Screen | Capable of tightly covered construction or long model easily; most suitable for fine powder in chemical, food and other industries. | Perfectly balanced type elastic drive using 3-phase induction motor and eccentric shaft. |

| Rubber Spring Screen | Used for feeding and screening materials, from fine to massive materials such as coke, sintered ore, and iron ore. | Resonance type consisting of 3-phase induction motor, unbalanced weight, and rubber spring. |

| LDS Type Linear Drive Screen | Large screen used for screening coke, coal, sintered ore, iron ore, copper ore, limestone, crushed stone, etc. Applicable as both dry and wet types. | Forced drive using 3-phase induction motor and unbalanced weight to get linear motion. |

| GYS Type Gyratory Screen | Suitable for fine powder to minute powder because screen cloth vibrates roundly without vertical vibration. Therefore, it is very rare to pass columnar materials. Thus, it’s suitable for special use such as removing pellet waste. | Horizontal swing using 3-phase induction motor, vertical eccentric shaft and roller. |

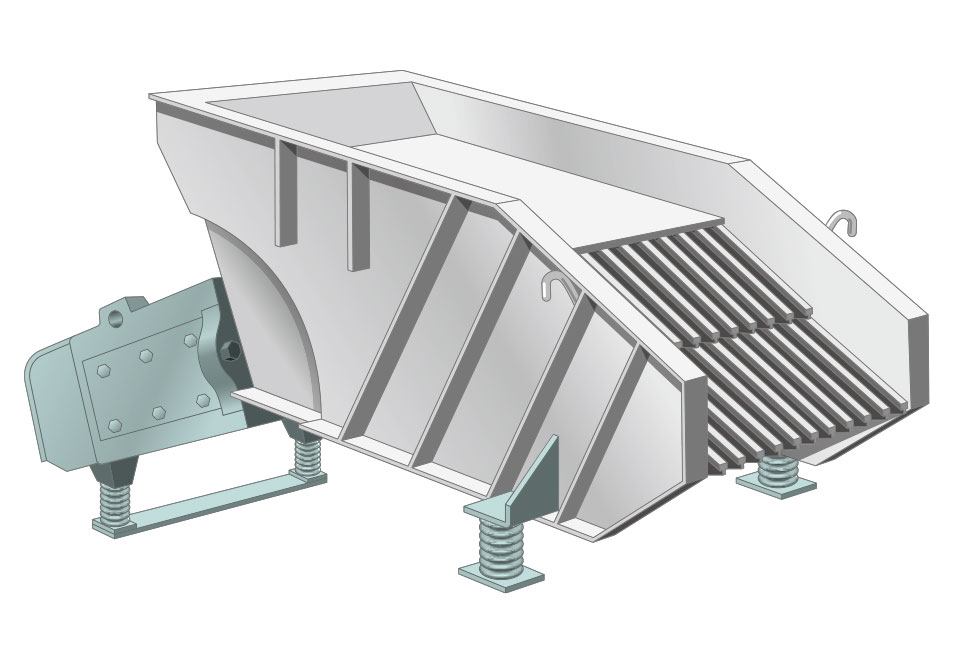

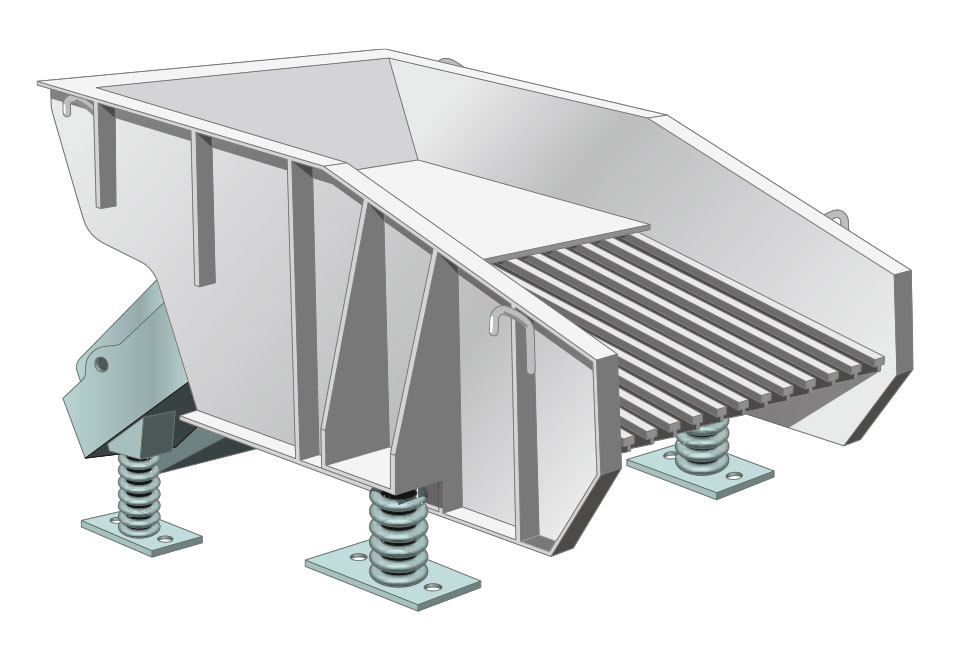

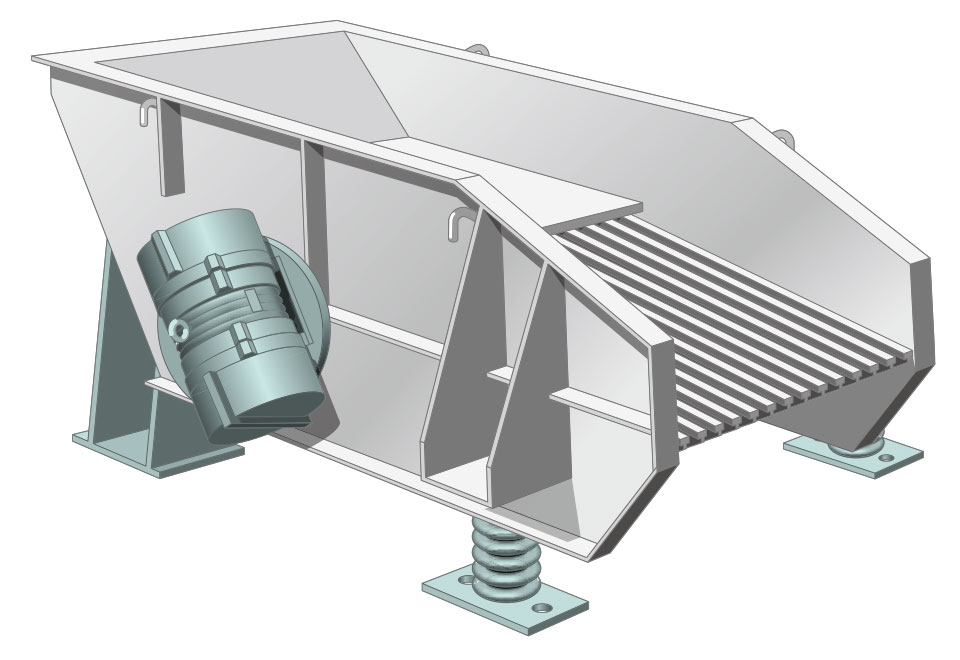

| GF⋅RGH⋅RVG Type Grizzly Feeder | Used for rough screening of quarried stuffs, such as crushed stone, iron ore, coal, and briquette. | GF…Electromagnetic type RGH…Electric motor type RVG…Vibrating motor type |

| KRS Type Wave Screen | Wave screen can handle various kinds of granular materials that used to be difficult to handle continuously in the past because of clog. This is especially suitable for humid materials such as piled. | Combination drive receiving mixture of both round vibration from 3-phased induction motor and unbalanced weight and elasticity of screen by rubber spring for resonant vibration. |

*1. Adjustable during the machine in operation.

*2. Adjustable when the machine is stopped.

*3. Marked models has a built-in clog preventing function without using tapping balls.

*Explosion proof types are available for*marked models (Drive unit only)

| Model | Stroke (mm) | Vibrations per min. 50/60Hz |

Stroke adjustment |

Clogging prevention |

Recommended screen opening |

Explosion proof structure |

Installation method |

||

|---|---|---|---|---|---|---|---|---|---|

| SF Type Electromagnetic Screen | 0~1.5 | 3000/3600 | *1 | - | 150mesh~50mm | * | Floor mounted⋅Suspension Horizontal or Quasi-horizontal | ||

| RVS Type Rotary Vibrating Screen | 4P | 2~4 | 1450/1710 | *2 | Tapping ball is required | 150mesh~30mm | * | Floor mounted⋅ Suspension Horizontal or Inclined | |

| 8P | 5~8 | 720/850 | |||||||

| SMVCB Type Balanced Screen | 8~18 | 450~650 | *2 | Tapping ball is required | 150mesh~50mm | - | Floor mounted Horizontal or Quasi-horizontal | ||

| SBM Type Perfect Balanced Screen | 8~20 | 450~650 | *2 | Tapping ball is required | 150mesh~50mm | * | Floor mounted Horizontal or Quasi-horizontal | ||

| Rubber Spring Screen | 6~7 | approx1100 | *1 | Tapping ball is required | 150 mesh~10mm | - | Floor mounted⋅Suspension Horizontal or Inclined | ||

| LDS Type Linear Drive Screen | 9~13 | 6P | 980/- | - | - | 5mm~50mm | * | Floor mounted Inclined | |

| 8P | -/880 | ||||||||

| GYS Type Gyratory Screen | 50~70 | 200~250 | - | *1 Tapping ball is required | 150mesh~1mm | * | Floor mounted Inclined | ||

| GF Type Grizzly Feeder | 0~1.5 | 3000/3600 | *1 | *3 | Grizzly bar Opening from more than 15mm | * | Floor mounted⋅ Suspension Quasi-horizontal or Inclined | ||

| RGH Type Grizzly Feeder | 6~7 | approx1100 | *1 | - | |||||

| RVG Type Grizzly Feeder | 2~8 | 720~850 | *2 | * | |||||

| KRS Type Wave Screen | Body Stroke 6mm Screen Stroke 16mm |

approx900 | *2 | Screen's own tension and looseness | 2mm~40mm | - | Floor mounted Inclined | ||

*1. Adjustable during the machine in operation.

*2. Adjustable when the machine is stopped.

*3. Marked models has a built-in clog preventing function without using tapping balls.

*Explosion proof types are available for*marked models (Drive unit only)

Features of Screen Cloth (Mesh screen)

There are several types of screen clothes such as woven wire screen, punch metal, rubber screen, and grizzly bar. Choosing the suitable screen is necessary in order to improve screening efficiency.

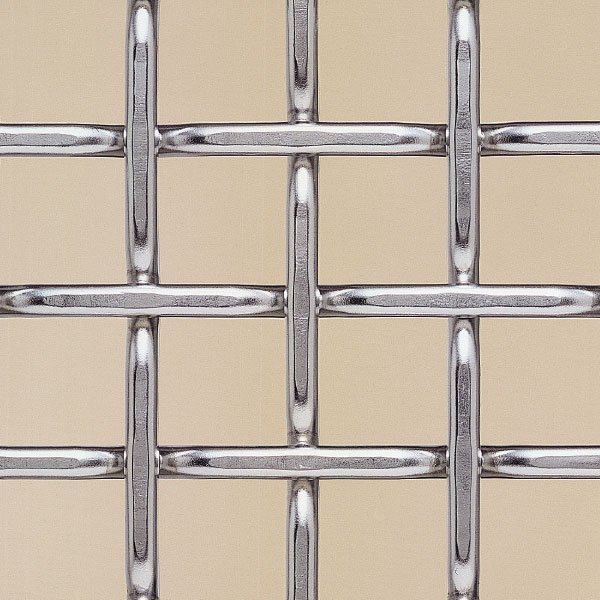

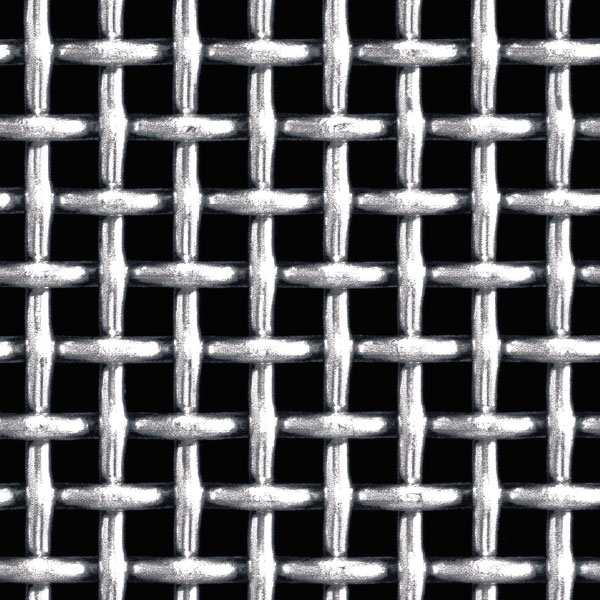

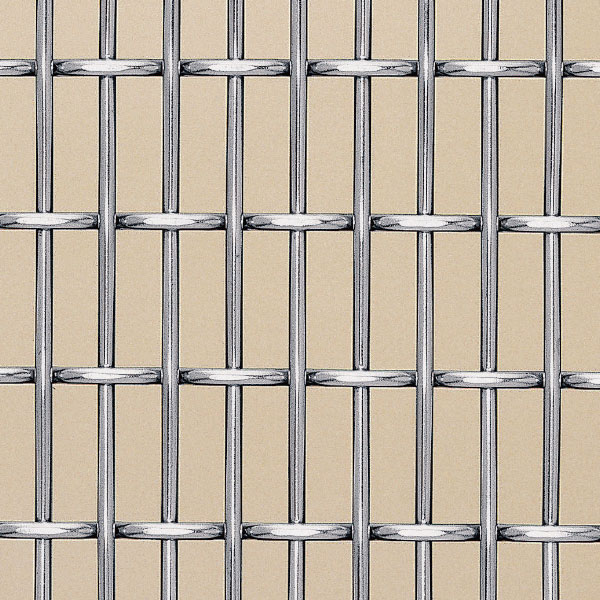

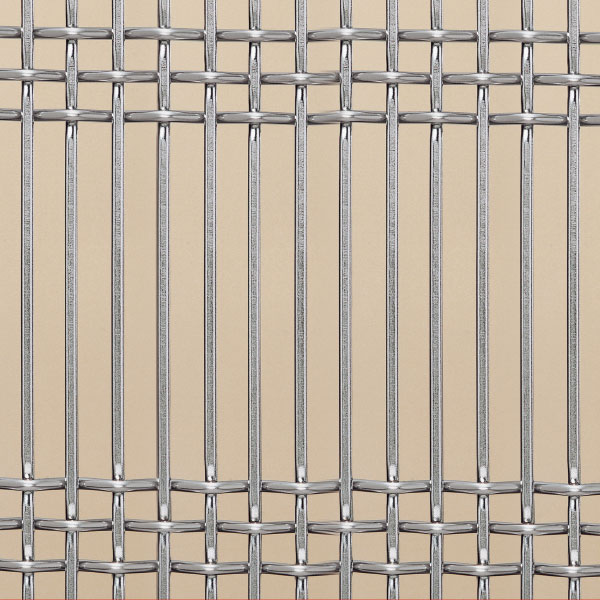

- Woven wire screen

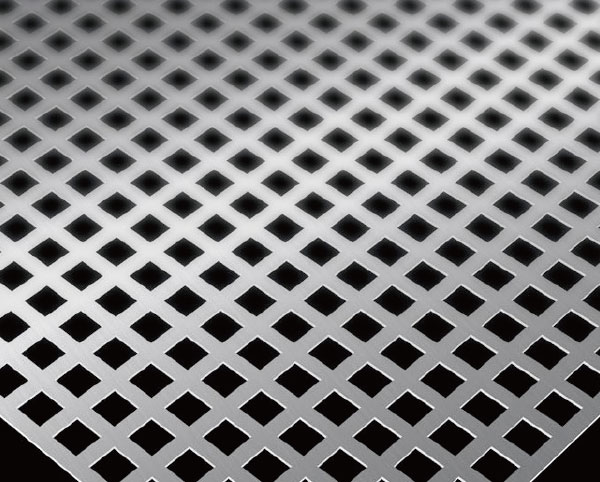

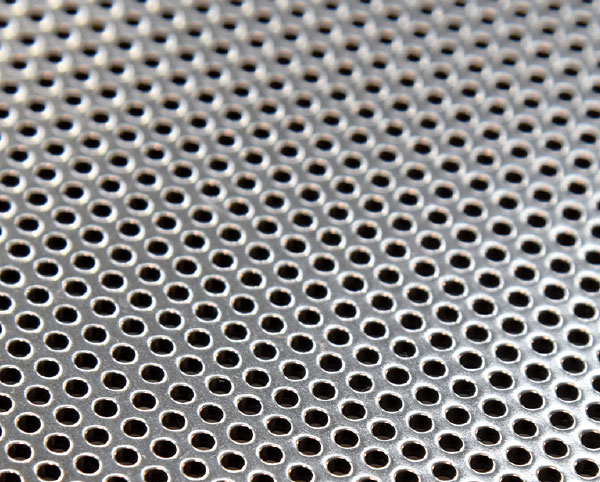

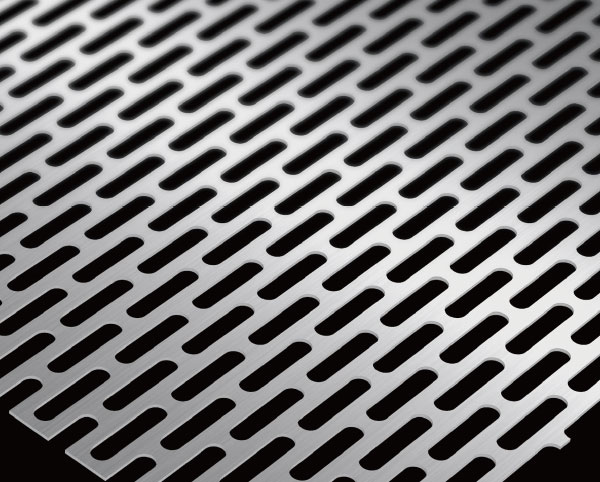

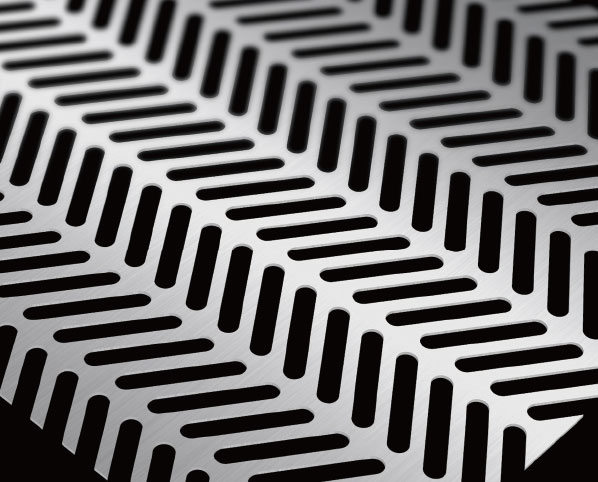

Plain weave and flat-top weave are mainly used for woven wire screens. However, Ton-cap weave and Tie-rod weave are also used for viscous materials and mass processing. Screens are usually made by hard steel wire, but galvanizing lines and stainless steel wire are used depending on the intended use. - Perforated metal screen

Square hole is mainly used for perforated metal screens, but there are various types available such as round hole, and Oblong. Steel board is usually used for punch metals, but High-tensile steel board and stainless steel board are also used depending on the intended use. - Rubber Screen

Square hole, round hole, and oblong are used for rubber screens. Structure of rubber screen depends on the manufacturing company. Therefore, there are products such as perforated abrasion resistance rubber board, and metallic molding type with a built in reinforcing cord and plate. - Grizzly bar

- Comb

Woven wire screen

Plain weave

Flat-top weave

Ton-cap weave

Tie-rod weave

Perforated metal screen

Square hole

Round hole

Oblongs

Herringbone

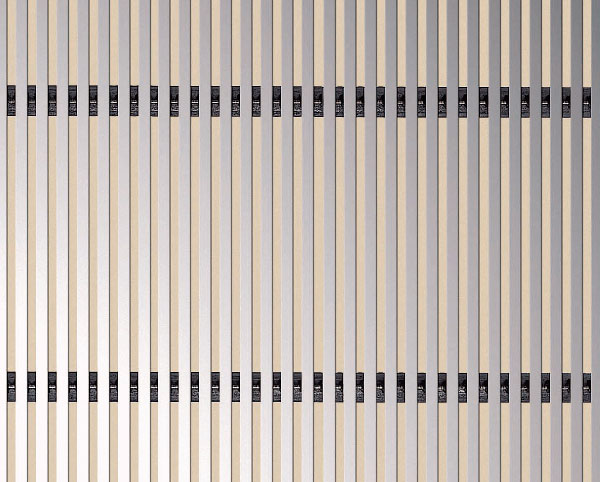

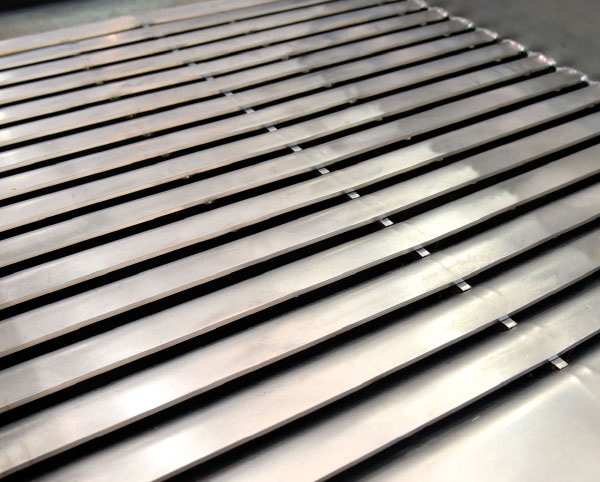

Special screen

Wedge wire

Louver

Comb

JIS Standard Screens (for fine sieves)

| Nominal size (μm) |

Screen opening | Wire (mm) | Converted mesh | Compatible Tyler mesh (%) | Void ratio (%) | Tyler mesh opening (mm) | |||

|---|---|---|---|---|---|---|---|---|---|

| Size (mm) | Tolerance (%) | Diameter | Tolerance | ||||||

| Mean | Max | ||||||||

| 5660 4760 4000 |

5.66 4.76 4.00 |

±2.5 ±2.5 ±2.5 |

10 10 10 |

1.600 1.290 1.080 |

±0.040 ±0.040 ±0.040 |

3.5 4.2 5 |

3.5 4 5 |

60.8 61.8 62.0 |

5.613 4.699 3.962 |

| 3360 2830 2380 2000 |

3.36 2.83 2.38 2.00 |

±3 ±3 ±3 ±3 |

10 10 10 10 |

0.870 0.800 0.800 0.760 |

±0.030 ±0.030 ±0.030 ±0.030 |

6 7 8 9.2 |

6 7 8 9 |

63.1 60.8 56.0 52.5 |

3.327 2.794 2.362 1.981 |

| 1680 1410 1190 1000 |

1.68 1.41 1.19 1.00 |

±3 ±3 ±3 ±5 |

10 10 10 15 |

0.740 0.710 0.620 0.590 |

±0.025 ±0.025 ±0.025 ±0.025 |

10.5 12 14 16 |

10 12 14 16 |

48.2 44.2 43.2 39.6 |

1.651 1.397 1.168 0.991 |

| 840 710 590 500 |

0.84 0.71 0.59 0.50 |

±5 ±5 ±5 ±6 |

15 15 15 15 |

0.430 0.350 0.320 0.290 |

±0.025 ±0.025 ±0.020 ±0.020 |

20 24 28 32 |

20 24 28 32 |

43.8 44.9 42.0 40.1 |

0.833 0.701 0.589 0.495 |

| 420 350 297 250 |

0.42 0.35 0.297 0.250 |

±6 ±6 ±6 ±6 |

25 25 25 25 |

0.290 0.260 0.232 0.174 |

±0.020 ±0.020 ±0.015 ±0.015 |

36 42 48 60 |

35 42 48 60 |

35.0 32.9 31.5 34.8 |

0.417 0.351 0.295 0.246 |

| 210 177 149 125 |

0.210 0.177 0.149 0.125 |

±6 ±6 ±6 ±6 |

25 25 40 40 |

0.153 0.141 0.105 0.087 |

±0.015 ±0.015 ±0.015 ±0.015 |

70 80 100 120 |

65 80 100 115 |

33.5 31.0 34.4 34.8 |

0.208 0.175 0.147 0.124 |

| 105 88 74 63 |

0.105 0.088 0.074 0.063 |

±6 ±7 ±7 ±7 |

40 40 60 60 |

0.070 0.061 0.053 0.039 |

±0.010 ±0.010 ±0.010 ±0.005 |

145 170 200 250 |

150 170 200 250 |

36.0 34.9 34.0 38.1 |

0.104 0.088 0.074 0.061 |

| 53 44 37 |

0.053 0.044 0.037 |

±8 ±8 ±8 |

60 60 90 |

0.380 0.028 0.026 |

±0.005 ±0.005 ±0.005 |

280 350 400 |

270 325 400 |

33.9 37.3 34.5 |

0.053 0.043 0.038 |

Screen Installation

1

2

3

4

5

6

Inlet, Outlet and Cover Examples

Inlet with square flange

Inlet with round flange

Oval Inlet

Circle Inlet

Outlet with square flange

Oval Outlet

Circle outlet

Outlet with flange

Oval, round outlet

Cover with inspection window

Cover: Iron, stainless steel

Inspection window: Soft or rigid vinyl chloride, acrylic, polycarbonate, rubber cap, or hole cap of the same quality as the cover

Left: Opaque cover (canvas, nylon tarpaulin)

Right: Transparent cover (soft and rigid vinyl chloride, acrylic, polycarbonate)

Standard cover (iron or stainless steel)

Other vibrating screens and vibrating equipment

For screening and size sorting... fastest and most even screening.

Rubber Spring Screen RSH Type

Linear vibration type screen using an unbalanced weight type vibrator and the resonant action of rubber springs. The large amplitude makes it highly efficient. The structure is easy to maintain and adjust, and the processing volume can be easily adjusted by the controller.

Electromagnetic screen VSF type

Electromagnetic vibration is applied directly to the screen attached to the frame. A small vibration source can vibrate a large area of screen. Ideal for processes with large returns.

For casting sand processing. Rapid separation of sand and product from the casting frame.

Shakeout Machine

This vibrating machine for casting sand processing efficiently separates products and sand from casting molds by applying vibration to the cast molds. The drive vibration motor can be freely adjusted in amplitude according to the size of the product to be separated and the condition of the sand. The products are conveyed from the deck plate to the next process. Operation, maintenance, and inspection are extremely easy. Ideal for streamlining sand processing lines.

Large volume feeding of medium and large lump material with bulk feeding.

Grizzly Feeder GF type

Half-wave pulsating current is used to excite an electromagnet, which is driven by high-speed and powerful vibration. It has excellent screening efficiency, and performs highly efficient roughing of large volumes of ore, crushed stone, lime, and other materials. The processing volume can be freely adjusted. Robust structure that can withstand heavy use.

Rubber Spring Grizzly Feeder RGH Type

Linear vibration type that effectively applies unbalanced weight vibrators and the resonant action of rubber springs. It is a versatile type that can carry out large-volume rough shaking with a small driving force. Of course, like the GF type, it demonstrates stable performance in any operating conditions.

RV Grizzly Feeder RVG Type

Forced vibration type with the vibrating motor mounted directly on the trough. The structure is lightweight and robust. The RVG type is also extremely stable in operation due to its high vibratory transmission efficiency to the trough and the amplitude increase phenomenon caused by material adhesion.

Strong screen ideal for sticky materials.

Wave Screen

Dynamic vibration of the screen, which alternately "tautens" and "sags", makes it ideal for screening sticky materials. The screen can be applied to a wide range of materials with high water content that are prone to clogging or sticking to the screen, and can be operated continuously.