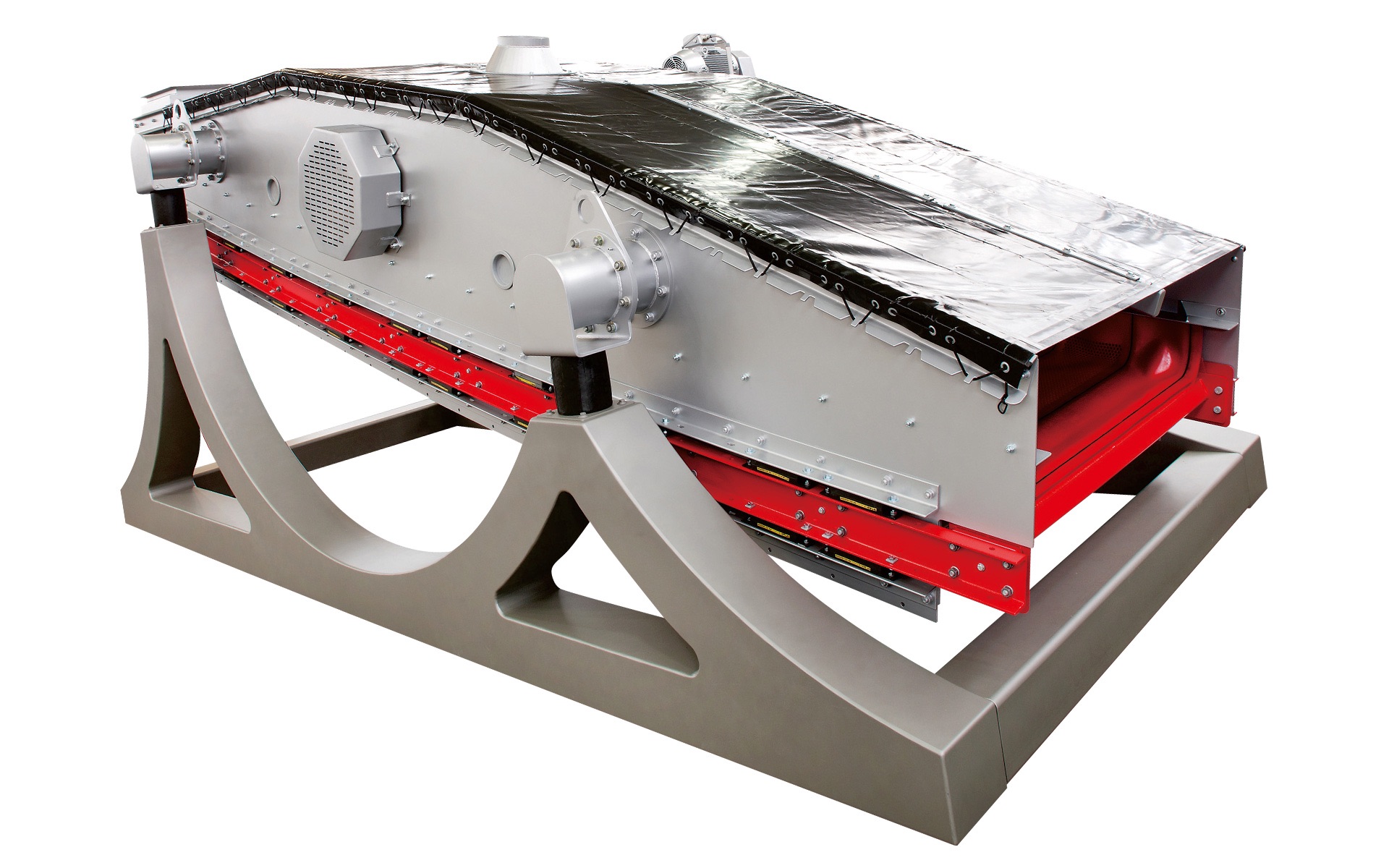

KRL The Wave Screen

A unique type of screen with a waving screen

The Wave Screen is a revolutionary screen with a vibrating mesh screen. The wavy screen gives a large acceleration force to the material, so that even moist or sticky materials can be screened efficiently without clogging. The screen can be applied to a wide range of materials with a standard classifying diameter of 2 to 35mm and is especially suitable for field piled materials.

Features

- No clogging due to the wavy screen

The dynamic vibration of the screen, which alternates between "tautens" and "sags", enables screening of materials that stick easily to the screen without clogging, which is difficult with conventional screens. - Easy replacement of the screen with a hammer (Figure A)

The screen is fixed by a special method that does not use any bolts. The screen can be easily replaced with a single hammer. - Small angle of downward movement reduces installation height.

The screen can be used with a downward angle of only 5° (standard 15°) because the screen is subjected to two vibrations (circular vibration of the drive unit and linear vibration of the vibrating frame due to resonance action), which give a large acceleration to the material. As a result, the installation height can be significantly reduced. - Flexible feeding and screening conditions

Depending on the feed rate and the moisture content of the applied material, it is easy to adjust the amplitude, vibration frequency, etc. by inverter control or by adjusting the angle of the unbalanced weight. - Sturdy structure and maintenance free

The body has a simple and reasonable structure. The screen is made of urethane, which permanently maintains high flexibility, and requires minimal maintenance. - Unique models are also available (Figure B)

Ox horn type model is also available, which looks like an ox horn. The screen is more durable, and material is less likely to leak through the gaps between the screen and the frame, making for more efficient operation.

Holding method without using bolt

Unique screen type “ox horn type”

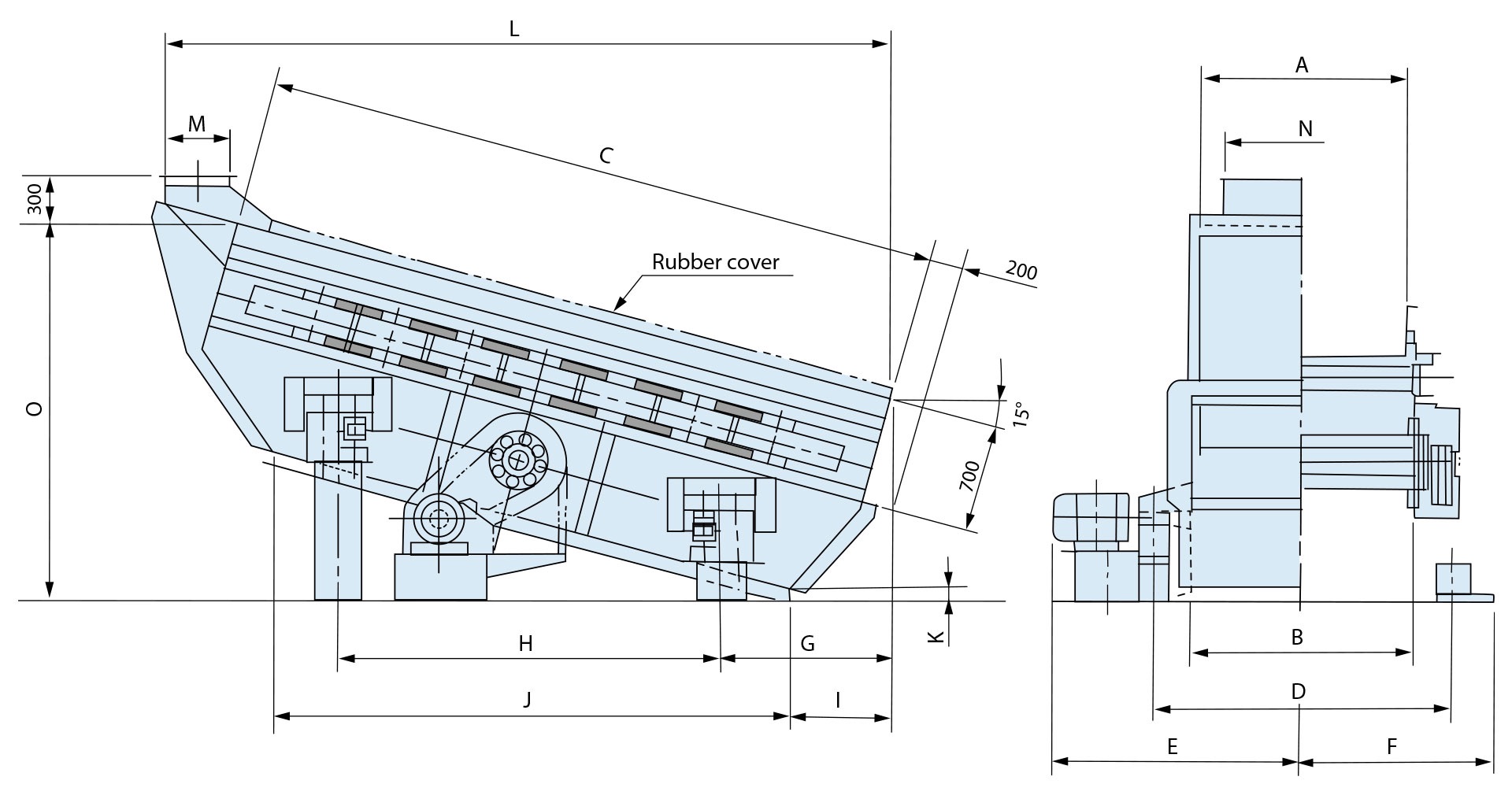

Structural Diagram

Specifications

Standard Specifications

| Model | Effective screening area (m2) |

Motor output (kW) |

Vibration per min. (50/60Hz.) |

Gross weight (kg) |

|---|---|---|---|---|

| KRS-800-2 | 1.5 | 5.5 | 900 | 2100 |

| KRS-800-3 | 2.3 | 7.5 | 900 | 2900 |

| KRS-800-4 | 3.1 | 7.5 | 900 | 3500 |

| KRS-1000-3 | 3.0 | 7.5 | 900 | 3300 |

| KRS-1000-4 | 4.0 | 11 | 900 | 4300 |

| KRS-1000-5 | 5.0 | 15 | 900 | 5000 |

| KRS-1000-6 | 6.0 | 15 | 900 | 5600 |

| KRS-1300-3 | 3.9 | 11 | 900 | 3600 |

| KRS-1300-4 | 5.2 | 11 | 900 | 4600 |

| KRS-1300-5 | 6.4 | 15 | 900 | 5500 |

| KRS-1300-6 | 7.7 | 18.5 | 900 | 6200 |

| KRS-1600-3 | 4.8 | 11 | 900 | 4900 |

| KRS-1600-4 | 6.3 | 15 | 900 | 6100 |

| KRS-1600-5 | 7.9 | 18.5 | 900 | 7400 |

| KRS-1600-6 | 9.5 | 22 | 900 | 8300 |

| KRS-1900-4 | 7.5 | 15 | 900 | 7400 |

| KRS-1900-5 | 9.4 | 18.5 | 900 | 8900 |

| KRS-1900-6 | 11.3 | 22 | 900 | 10000 |

| KRS-2200-5 | 10.9 | 22 | 900 | 10200 |

| KRS-2200-6 | 13.0 | 30 | 900 | 11700 |

| KRS-2400-5 | 11.9 | 30 | 900 | 11500 |

| KRS-2400-6 | 14.2 | 30 | 900 | 13500 |

Outer Dimensions

Dimension Table

Unit: mm

| Model | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KRS-800-2 | 780 | 880 | 2250 | 1300 | 1150 | 850 | 600 | 1500 | 324 | 2173 | 110 | 2511 | 300 | 750 | 1900 |

| KRS-800-3 | 780 | 880 | 3230 | 1300 | 1200 | 850 | 800 | 1900 | 549 | 2434 | 167 | 3458 | 300 | 750 | 2150 |

| KRS-800-4 | 780 | 880 | 4220 | 1300 | 1200 | 850 | 1050 | 2400 | 549 | 3391 | 161 | 4414 | 300 | 750 | 2400 |

| KRS-1000-3 | 1010 | 1110 | 3230 | 1600 | 1400 | 1000 | 800 | 1900 | 549 | 2434 | 167 | 3458 | 300 | 800 | 2150 |

| KRS-1000-4 | 1010 | 1110 | 4220 | 1600 | 1450 | 1050 | 1050 | 2400 | 620 | 3231 | 76 | 4414 | 300 | 800 | 2400 |

| KRS-1000-5 | 1010 | 1110 | 5200 | 1600 | 1500 | 1050 | 1300 | 2900 | 620 | 4177 | 73 | 5361 | 300 | 800 | 2650 |

| KRS-1000-6 | 1010 | 1110 | 6190 | 1600 | 1500 | 1100 | 1300 | 3900 | 655 | 5053 | 24 | 6317 | 300 | 800 | 2900 |

| KRS-1300-3 | 1310 | 1410 | 3230 | 1900 | 1550 | 1150 | 800 | 1900 | 549 | 2434 | 167 | 3555 | 400 | 1000 | 2150 |

| KRS-1300-4 | 1310 | 1410 | 4220 | 1900 | 1600 | 1200 | 1050 | 2400 | 620 | 3231 | 76 | 4511 | 400 | 1000 | 2400 |

| KRS-1300-5 | 1310 | 1410 | 5200 | 1900 | 1650 | 1200 | 1300 | 2900 | 620 | 4177 | 73 | 5458 | 400 | 1000 | 2650 |

| KRS-1300-6 | 1310 | 1410 | 6190 | 1900 | 1650 | 1250 | 1300 | 3900 | 655 | 5053 | 24 | 6414 | 400 | 1000 | 2900 |

| KRS-1600-3 | 1610 | 1710 | 3230 | 2200 | 1750 | 1300 | 850 | 1800 | 620 | 2274 | 82 | 3555 | 400 | 1200 | 2150 |

| KRS-1600-4 | 1610 | 1710 | 4220 | 2200 | 1800 | 1350 | 1050 | 2400 | 620 | 3131 | 76 | 4511 | 400 | 1200 | 2400 |

| KRS-1600-5 | 1610 | 1710 | 5200 | 2200 | 1800 | 1350 | 1300 | 2900 | 655 | 4097 | 30 | 5458 | 400 | 1200 | 2650 |

| KRS-1600-6 | 1610 | 1710 | 6190 | 2200 | 1800 | 1400 | 1300 | 3900 | 726 | 4893 | -10 | 6414 | 400 | 1200 | 2950 |

| KRS-1900-4 | 1910 | 2010 | 4220 | 2500 | 1950 | 1500 | 1050 | 2400 | 655 | 3323 | 34 | 4511 | 400 | 1300 | 2400 |

| KRS-1900-5 | 1910 | 2010 | 5200 | 2500 | 1950 | 1550 | 1300 | 2900 | 726 | 3937 | -4 | 5458 | 400 | 1300 | 2700 |

| KRS-1900-6 | 1910 | 2010 | 6190 | 2500 | 1950 | 1550 | 1300 | 3850 | 726 | 4893 | -10 | 6414 | 400 | 1300 | 2950 |

| KRS-2200-5 | 2210 | 2310 | 5200 | 2850 | 2100 | 1725 | 1300 | 2900 | 726 | 3937 | -4 | 5554 | 500 | 1500 | 2700 |

| KRS-2200-6 | 2210 | 2310 | 6190 | 2850 | 2200 | 1825 | 1300 | 3850 | 868 | 4746 | -130 | 6510 | 500 | 1500 | 3000 |

| KRS-2400-5 | 2410 | 2510 | 5200 | 3050 | 2300 | 1825 | 1300 | 2900 | 868 | 3789 | -173 | 5554 | 500 | 1600 | 2700 |

| KRS-2400-6 | 2410 | 2510 | 6190 | 3050 | 2300 | 1925 | 1300 | 3850 | 868 | 4746 | -130 | 6510 | 500 | 1600 | 3000 |

Troughs are standard with lid or bottomless.

Two-stage screens are also available.