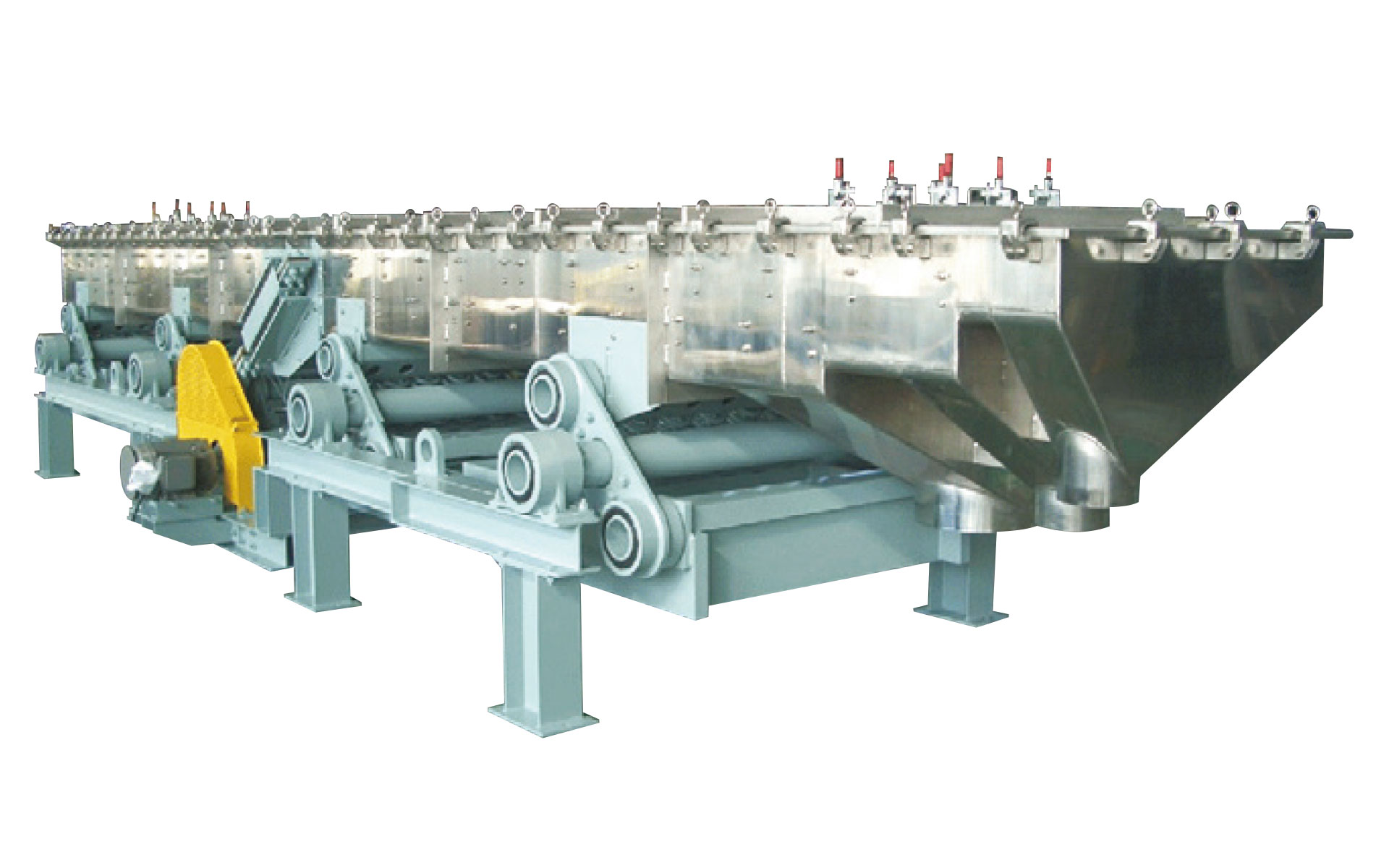

SBM Type Perfect Balanced Screen

Perfect Balanced Screens

With the SINFONIA SBM Type BM Screens, the upper or lower trough is counter-weighted to increase efficiency from the viewpoint of "balance" during on-load operation.

This model facilitates long length and enclosed contruction. It is especially suited for handling fine powder materials in the chemical and food industries.

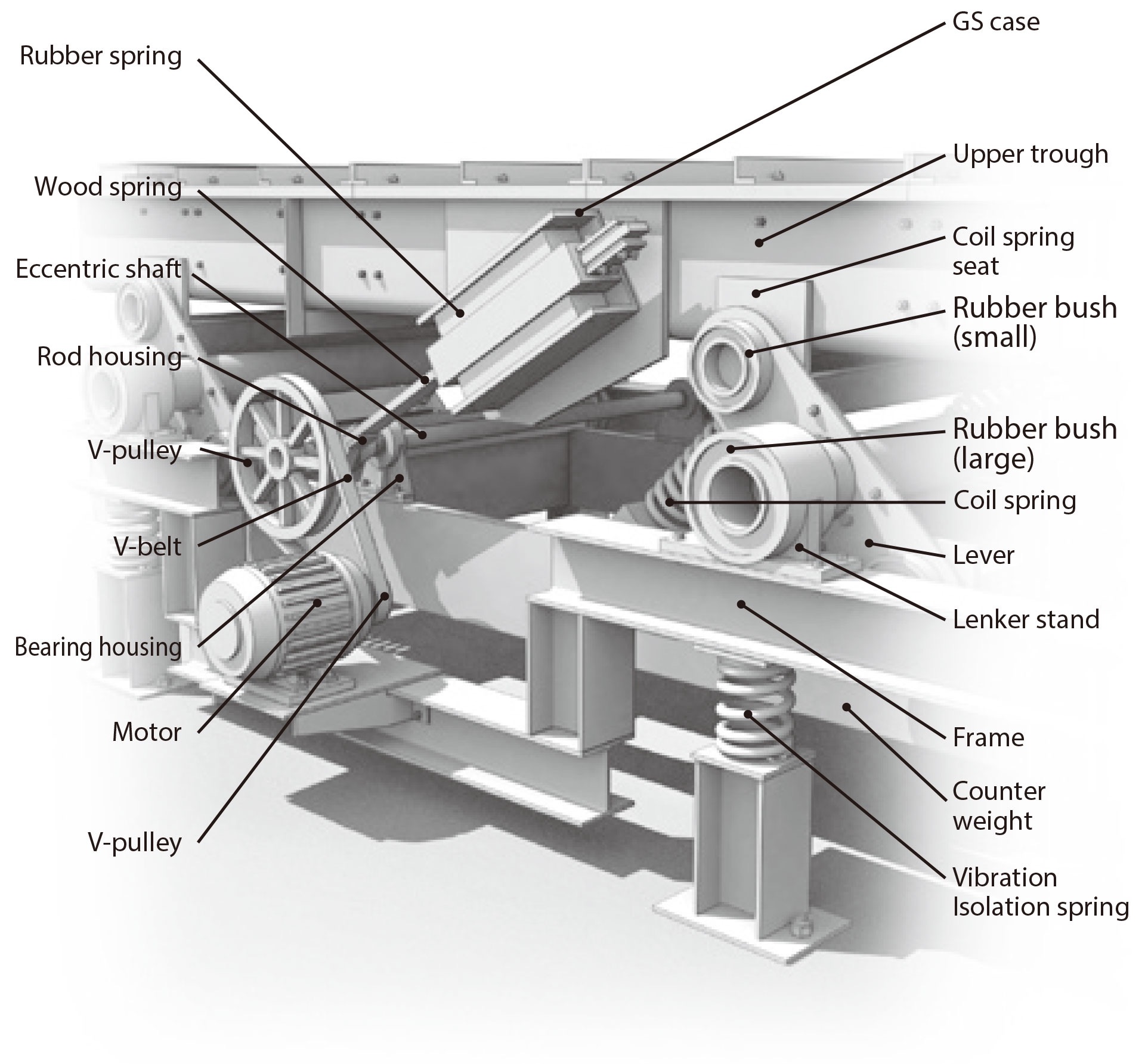

Features

- Perfect anti-vibration structure

The fully balanced design prevents vibration from being transmitted to the mounting base. Therefore, installation on a high base is possible. If the foundation is solid, such as concrete, it can be installed without the anti-vibration spring to lower the overall height. - High efficiency

In consideration of balance under load, one of the upper and lower troughs is used as a counterweight to increase efficiency. - Easily sealed and long structure

Various covers are available for easy installation in an enclosed structure, and in the case of a long trough, the troughs can be connected and assembled in 5 to 8m lengths.

Structural Diagram

Specifications

Standard Specifications

Single-deck screen

| Model | Effective screening area (m2) |

Motor output (kW×number of units) |

Vibration per min. (50/60Hz) |

Gross weight (kg) |

|---|---|---|---|---|

| SBM-450-2.5 | 0.7 | 1.5×1 | 450~650 | 1100 |

| SBM-600-2.5 | 1.0 | 2.2×1 | 450~650 | 1400 |

| SBM-600-3.0 | 1.2 | 2.2×1 | 450~650 | 1500 |

| SBM-750-2.5 | 1.3 | 2.2×1 | 450~650 | 1750 |

| SBM-750-3.0 | 1.6 | 3.7×1 | 450~650 | 1900 |

| SBM-900-2.5 | 1.6 | 3.7×1 | 450~650 | 2200 |

| SBM-900-3.0 | 2.0 | 3.7×1 | 450~650 | 2300 |

| SBM-900-3.5 | 2.4 | 3.7×1 | 450~650 | 2600 |

| SBM-1200-3.0 | 2.7 | 2.2×1 | 450~650 | 3000 |

| SBM-1200-3.5 | 3.3 | 3.7×2 | 450~650 | 3200 |

| SBM-1200-4.0 | 3.8 | 3.7×2 | 450~650 | 3550 |

| SBM-1500-3.5 | 4.2 | 3.7×2 | 450~650 | 4100 |

| SBM-1500-4.0 | 4.9 | 3.7×2 | 450~650 | 4650 |

Double-deck screen

| Model | Effective screening area (m2) |

Motor output (kW×number of units) |

Vibration per min. (50/60Hz) |

Gross weight (kg) |

|---|---|---|---|---|

| SBM-450-2.5 | 0.68 | 1.5×1 | 450~650 | 1300 |

| SBM-600-2.5 | 0.98 | 2.2×1 | 450~650 | 1650 |

| SBM-600-3.0 | 1.15 | 2.2×1 | 450~650 | 1750 |

| SBM-750-2.5 | 1.2 | 3.7×1 | 450~650 | 2050 |

| SBM-750-3.0 | 1.5 | 3.7×1 | 450~650 | 2200 |

| SBM-900-2.5 | 1.5 | 3.7×1 | 450~650 | 2550 |

| SBM-900-3.0 | 1.85 | 3.7×1 | 450~650 | 2650 |

| SBM-900-3.5 | 2.25 | 2.2×2 | 450~650 | 3000 |

| SBM-1200-3.0 | 2.8 | 3.7×2 | 450~650 | 3450 |

| SBM-1200-3.5 | 3.6 | 3.7×2 | 450~650 | 3700 |

| SBM-1200-4.0 | 3.7 | 3.7×2 | 450~650 | 4100 |

| SBM-1500-3.5 | 4.0 | 3.7×2 | 450~650 | 4700 |

| SBM-1500-4.0 | 4.7 | 3.7×2 | 450~650 | 5400 |

Outer Dimensions

Dimension Table

Unit: mm

| Model | A | B | C | D (MAX) | E | F | |||

|---|---|---|---|---|---|---|---|---|---|

| SBM-450 | 450 | 2500 | - | - | - | 1000 | approx 820 | 1400±30 | 400 |

| SBM-600 | 600 | 2500 | 3000 | - | - | 1150 | approx 940 |

1400±30 |

500 |

| SBM-750 | 750 | 2500 | 3000 | - | - | 1350 | approx 1040 |

1400±30 |

650 |

| SBM-900 | 900 | 2500 | 3000 | 3500 | - | 1500 | approx 1270 |

1400±30 |

800 |

| SBM-1200 | 1200 | - | 3000 | 3500 | 4000 | 1800 | approx 1420 |

1400±30 |

1100 |

| SBM-1500 | 1500 | - | - | 3500 | 4000 | 2100 | approx 1570 |

1400±30 |

1400 |